A Complete Overview of Sewage Pump Installation Costs and Considerations

When managing wastewater in residential, commercial, or industrial settings, sewage pumps play a crucial role. Whether you're handling household waste, draining flooded areas, or managing construction site dewatering, installing the right type of pump is essential. This guide will take a detailed look at different types of sewage pumps, their installation costs, key considerations, and ongoing maintenance requirements.

Types of Sewage Pumps

Choosing the right pump is essential for efficient wastewater management. Below are the common types of pumps used for sewage, dewatering, and drainage purposes, each with its own distinct features and price ranges:

a) Submersible Pump

A submersible pump is a widely used type that operates while being submerged in water. Its sealed motor ensures that it remains protected from moisture and debris, making it an excellent option for sewage and other waste management applications. Submersible pumps are favored for their quiet operation and ability to handle solid waste without clogging.

b) Submersible Pump 1 HP

When selecting a pump, power plays a key role in determining efficiency. A submersible pump 1 hp is a common choice for small to medium-sized residential systems, handling moderate volumes of wastewater and small solid particles. It offers a balance between performance and energy consumption.

c) Submersible Pump 1.5 HP

For higher capacity systems, a submersible pump 1.5 hp is often required. This type of pump is suitable for larger homes or commercial buildings with a greater wastewater output. It can manage more substantial loads and handle larger solids, making it ideal for heavy-duty sewage systems.

d) Submersible Water Pump

A submersible water pump is designed for removing clean or dirty water, making it versatile for various applications such as draining flooded basements or emptying swimming pools. These pumps are typically used in both residential and commercial settings.

e) Dewatering Pump

The dewatering pump is essential in construction and mining industries for removing water from sites, preventing flooding, and keeping work areas dry. This pump is capable of handling both clear and muddy water, making it a robust choice for industrial applications.

f) Best Submersible Pump

Selecting the best submersible pump involves considering factors like flow rate, pump capacity, material durability, and motor efficiency. High-quality pumps made from stainless steel or cast iron are recommended for longevity and better performance in sewage management.

g) Slurry Pump

A slurry pump is designed to handle thick, abrasive mixtures of water and solids. This type of pump is commonly used in industries that deal with heavy sludge, such as mining or wastewater treatment facilities. Slurry pumps are built to withstand harsh conditions and transport materials that would clog or wear out regular pumps.

h) Single Phase Submersible Pump

For residential use, the single phase submersible pump is a preferred option. It runs on standard household electricity and provides sufficient power for typical household wastewater management tasks. This type of pump is user-friendly and cost-effective.i) Drainage Pump

A Drainage pump is specifically designed to remove excess water from areas like basements, construction sites, or low-lying land. It helps in preventing water damage and maintaining dry conditions, particularly after heavy rains or flooding.

j) Sludge Pump

A sludge pump is a specialized pump for moving thick sludge, a mixture of solid and liquid components. These pumps are often used in sewage treatment plants or industrial settings where waste products are heavily concentrated. They are built to handle the toughest waste materials efficiently.

k) Sewage Sludge Pump

The sewage sludge pump is designed to move semi-solid waste materials that are too dense for regular pumps. These pumps are integral to wastewater treatment plants, ensuring the efficient transport of sludge from collection points to treatment areas.

l) Submersible Sewage Pump

A submersible sewage pump is submerged in the wastewater basin, and its primary function is to move sewage out of buildings where gravity alone isn’t sufficient. These pumps are durable and able to handle solids, making them the most reliable choice for homes or commercial sewage systems.

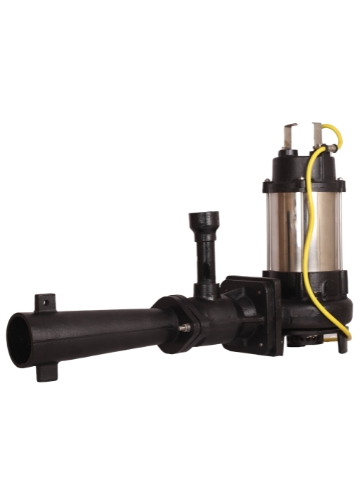

m) Cutter Pump

The Cutter Pump is designed to cut and shred solid materials before they pass through the pump, ensuring smooth operation without clogging. This feature is essential in settings where waste contains a high amount of debris.

n) Cutter Pump Sewage

In sewage management, the cutter pump sewage system ensures that large solid wastes are chopped up and passed through the system without causing blockages. It is highly efficient in commercial and industrial applications where solid waste is prevalent.

Key Cost Factors for Sewage Pump Installation

Several factors can influence the overall cost of installing a sewage pump. Understanding these factors helps in making informed decisions when selecting the right system for your home or business.

a) Pump Capacity

The capacity of the pump, typically measured in gallons per hour (GPH) or horsepower (HP), directly affects the cost. For example, a submersible pump 1 hp typically costs between $150 and $300, while a submersible pump 1.5 hp could range from $300 to $600. For large industrial pumps, the price could escalate to several thousand dollars[5][6].

b) Material

The construction materials of the pump also impact the cost. Pumps made from high-quality materials like cast iron or stainless steel are more expensive but offer superior durability. A sludge pump or submersible slurry pump made from durable materials can range from $500 to $2,000 depending on the specifications.

c) Labor Costs

Installation is typically not a DIY task, and professional labor costs range from $50 to $200 per hour, depending on the region. Most installations take 6 to 10 hours, so labor costs can vary from $300 to $2,000.

d) Additional Components

Some pumps require additional components like basins, control panels, and alarms. These accessories add to the cost but are essential for proper functionality. For instance, a submersible sewage pump might need a dedicated alarm system to prevent overflows.

Installation Process Overview

Proper installation is crucial for ensuring the longevity and reliability of your sewage pump system. The process generally involves the following steps:

- Site Preparation: This includes excavation and plumbing adjustments to accommodate the new pump.

- Pump Installation: The submersible pump, sludge pump, or cutter pump sewage is placed in the appropriate location, and connections to the plumbing system are made.

- Testing: After installation, the system is tested for leaks, flow efficiency, and overall performance.

Additional Costs to Consider

While the pump and installation are the most significant expenses, there are additional costs to consider:

a) Maintenance and Repairs

Regular maintenance is essential to keep your pump functioning optimally. Cleaning and inspecting the pump twice a year can prevent costly repairs. Maintenance costs typically range from $100 to $300 annually[7][8].

b) Upgrades and Alarms

Many modern pumps come with advanced features such as digital float switches and smart alarms. These systems notify the homeowner of any issues via text or email, providing peace of mind and preventing potential disasters.

c) Permits and Compliance Fees

Depending on your local building codes, you may need permits for installing a new sewage pump. Permit costs can vary, and it's essential to check with your local authorities before beginning any installation.

Dewatering and Construction Applications

Beyond sewage management, pumps are crucial in construction and industrial applications, especially dewatering pumps for construction. These pumps are essential in keeping job sites dry and preventing damage during excavation or groundwork.

a) Submersible Dewatering Pump

A submersible dewatering pump is designed to handle both clean and dirty water, making it ideal for construction sites. These pumps are typically more robust than standard residential models.

b) Dewatering Pump 1 HP

For smaller construction projects, a dewatering pump 1 HP offers a balance of power and efficiency, ensuring the site remains dry without excessive energy consumption.

c) Submersible Agitator Pump

The submersible agitator pump is equipped with an agitator at the base, helping to stir up solids and prevent clogging in applications like slurry pumping. This pump is useful in mining or construction sites where solids and liquids need to be moved simultaneously.

d) Slurry Pump Manufacturers

Top slurry pump manufacturers offer high-quality pumps designed to handle abrasive materials like sand, sludge, and gravel. These pumps are built for heavy-duty applications and are used extensively in mining and industrial processes.

e) Dewatering Pump Manufacturers

Reputable dewatering pump manufacturers provide pumps designed to handle challenging conditions in construction and industrial settings. Their pumps ensure durability and reliable performance, even in extreme environments.

Choosing the Right Pump Manufacturer

When selecting a pump, it's crucial to choose from reliable slurry pump manufacturers or sludge pump manufacturers who offer durable and efficient products. Leading manufacturers provide detailed technical specifications and offer support throughout the installation process.

Conclusion

Understanding the costs and considerations for installing a sewage pump or dewatering pump is crucial to making an informed decision. Whether you are managing residential wastewater, working on a construction site, or handling industrial waste, selecting the right pump ensures efficient and reliable operation of your wastewater management system.