Submersible water pumps have revolutionized the way water is moved and managed across industries. From draining flooded basements to powering irrigation systems, these pumps have become indispensable tools. This article provides an in-depth explanation of how submersible water pumps work, their key components, and applications, while also highlighting the various types like dewatering pumps, sewage pumps, and more.

What is a Submersible Water Pump?

A submersible water pump is a mechanical device designed to operate underwater, pushing water to the surface through a motor-driven impeller. Unlike other pumps that rely on suction, a submersible pump eliminates air handling issues, making it highly efficient. The sealed motor design prevents water ingress while enabling safe operation in diverse aquatic environments from clean wells to contaminated sewage systems.

Key Features

- Complete submersion capability allowing operation deep underwater without external housing or priming requirements

- Sealed motor design protecting electrical components from water exposure and environmental contamination

- Centrifugal force operation enabling efficient water movement without relying on suction lifting water vertically

- Corrosion-resistant materials including stainless steel, cast iron, and specialized alloys withstanding diverse fluid environments

- Thermal protection systems preventing motor overheating during continuous operation or restricted flow conditions

- Quiet operation from full submersion dampening vibration transmission and reducing noise pollution

- Robust construction designed for reliable operation in harsh conditions including mining, wastewater, and industrial applications

- Flexible power configurations available as single-phase, three-phase, and solar-powered models accommodating varied electrical infrastructure

- Compact design requiring minimal surface infrastructure and installation space

Types of Submersible Pumps

- Water Supply Pumps: Designed for clean or slightly contaminated groundwater, supplying residential and commercial water systems with consistent pressure and flow

- Submersible Sewage Pumps: Engineered to handle raw sewage containing solids and organic matter, featuring non-clogging impeller designs and robust construction

- Submersible Sump Pumps: Compact units installed in basement sump pits, managing groundwater accumulation and preventing flooding with automatic float-switch operation

- Submersible Dewatering Pumps: High-capacity models for rapid water removal from excavations, construction sites, and flooded areas with continuous high-volume discharge

- Submersible Slurry Pumps: Specialized for mining and industrial applications, featuring reinforced components handling abrasive, solid-laden fluids without damage

- Submersible Drainage Pumps: Portable units for landscape drainage, basement dewatering, and general water removal applications with flexible flow ratings

- Submersible Sewage Sludge Pumps: Heavy-duty models handling thick, viscous sludges in wastewater treatment with high-torque motors and oversized passages

- Submersible Agitator Pumps: Combining pumping action with mechanical stirring, maintaining sediment suspension in treatment tanks and holding pits

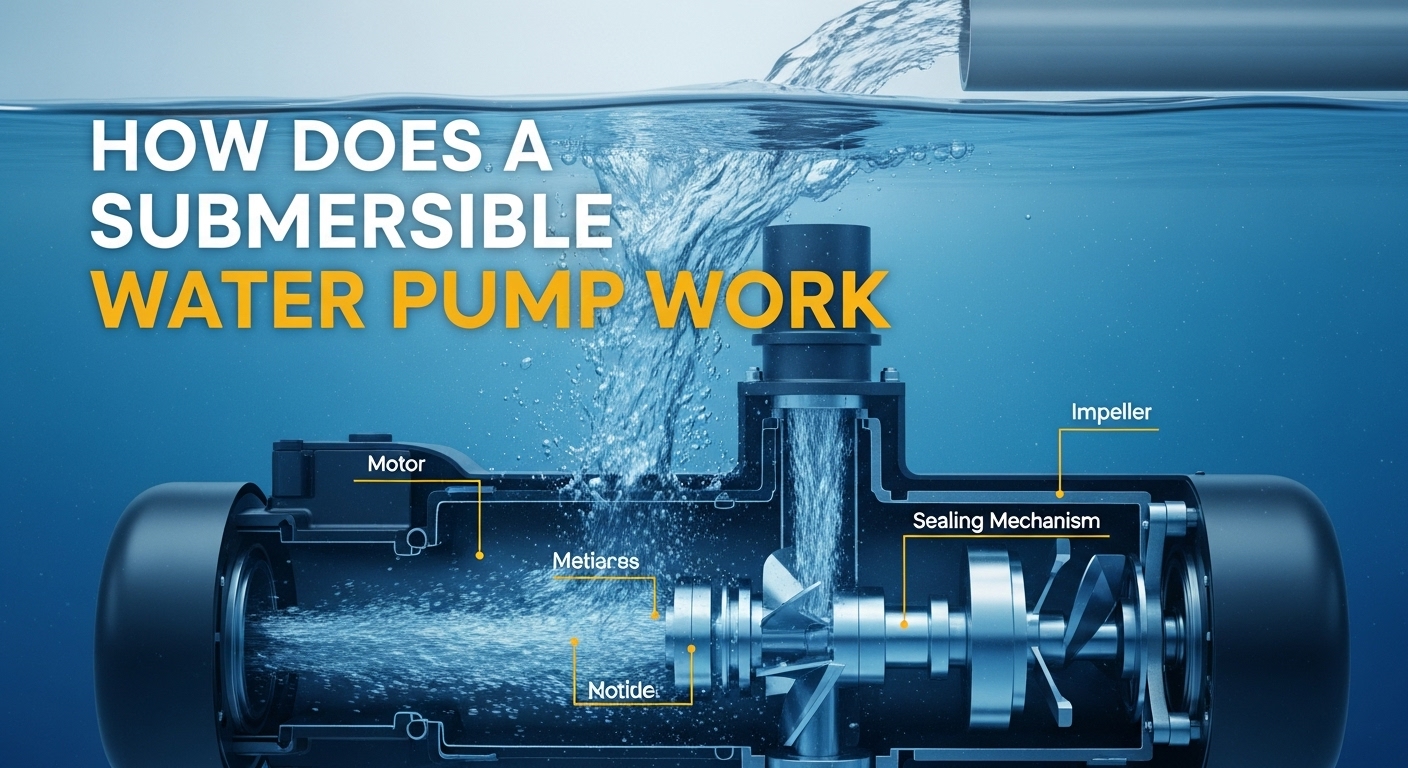

Components of a Submersible Water Pump

Understanding the components helps demystify the working of a submersible pump. Here's a breakdown of the essential parts:

| Component | Function and Details |

|---|---|

| Motor | Powers the impeller and is sealed to prevent water ingress. Designed for underwater operation with thermal protection and corrosion resistance. Available in various horsepower ratings accommodating different flow and pressure requirements |

| Impeller | Creates the flow of water by generating centrifugal force. Rotating blades accelerate water outward, creating pressure differences that move fluid from intake to discharge. Optimized designs reduce turbulence and energy loss improving overall efficiency |

| Sealing Mechanism | Prevents water from entering the motor, ensuring durability and safe operation. Multiple seal stages protect against gradual water penetration. Mechanical seals with carbon and ceramic materials withstand chemical exposure in diverse fluid environments |

| Housing | Protects internal components and ensures structural integrity in underwater conditions. Corrosion-resistant materials prevent degradation from salt water, chemicals, or abrasive slurries. Streamlined design minimizes resistance and improves hydraulic efficiency |

| Intake Strainer | Filters debris and solids preventing damage to the impeller and pump internals. Regular cleaning maintains adequate flow and prevents cavitation. Larger passages in heavy-duty models accommodate trash and solids in contaminated applications |

| Discharge Port | Routes pressurized water to external piping. Check valves prevent backflow when pumps shut down. Optimized designs minimize pressure drop and enable flexible discharge configurations accommodating various installation scenarios |

| Bearing System | Supports rotating shaft and impeller while minimizing friction. Water-lubricated or oil-lubricated designs depending on application. Advanced bearing materials extend lifespan and improve efficiency even in abrasive environments |

| Electrical Cable | Delivers power from surface electrical source to submerged motor. Heavy-duty insulation and weatherproof connectors protect against water exposure. Submersible-rated cables meet safety standards for underwater electrical transmission |

How Does a Submersible Water Pump Work?

A submersible pump works based on the principle of centrifugal force. Here's a step-by-step explanation of the operational process:

- Submersion: The pump is placed entirely underwater in the fluid requiring movement. Complete immersion enables direct water access and eliminates suction requirements that limit conventional pumps

- Activation: When powered, the motor drives the impeller at high rotational speeds. Electrical power converts to mechanical rotation enabling continuous operation under controlled conditions

- Water Intake: Water enters through an inlet port equipped with strainers filtering debris. Centrifugal force created by the rotating impeller draws water inward toward the center, creating pressure gradients moving fluid from the intake

- Pressure Creation: The impeller spins, creating pressure that forces water outward. Centrifugal acceleration generates pressure differences moving water from high-pressure to low-pressure areas. The volute chamber surrounding the impeller directs flow toward the discharge port

- Discharge: Water is expelled through an outlet pipe at elevated pressure and velocity. Check valves prevent backflow, ensuring one-directional fluid movement. Discharge piping routes water to treatment systems, storage tanks, or environmental discharge points

Why Submersible Pumps Are Effective

- Eliminates Cavitation Issues: By operating fully submerged, these pumps avoid suction-side cavitation problems that plague surface pumps trying to lift water from depth. Direct immersion enables operation at depths where surface pumps would cavitate and fail

- Maximizes Hydraulic Efficiency: Water surrounding the pump provides cooling and lubrication while minimizing energy losses. Efficient centrifugal design converts motor power directly to fluid movement without losses from air handling or suction-side friction

- Enables Continuous Unattended Operation: Sealed design and automatic controls enable reliable operation without supervision. Float switches, timers, and level sensors automate operation responding to changing conditions. Extended operation in harsh environments without maintenance intervention

- Handles Diverse Fluid Types: Specialized designs accommodate clean water, sewage, slurries, and chemicals. Cutter mechanisms process solids in sewage applications. Reinforced components withstand abrasive slurries in mining. Corrosion-resistant materials handle chemical exposure

- Reduces Infrastructure Requirements: Eliminating need for external pump houses or protective structures. Compact submersible design fits standard wells, sumps, and pits. Minimal surface infrastructure reduces installation costs and visual impact

- Provides Superior Reliability: Sealed design protects components from environmental damage, dust, and contaminants. Submerged operation maintains optimal motor temperature preventing overheating. Straightforward installation and maintenance extend equipment lifespan significantly

Applications of Submersible Water Pumps

Domestic Applications

- Well Water Supply: Submersible pumps installed in residential wells deliver drinking water directly to homes, eliminating dependence on municipal systems. These pumps maintain consistent pressure enabling reliable household water access regardless of seasons or weather conditions

- Basement Dewatering: Sump pumps automatically remove groundwater and surface water accumulating in basements, preventing flooding that would damage property and create safety hazards. Automatic operation activates when water levels rise, protecting homes during heavy rainfall periods

- Garden and Lawn Irrigation: Compact submersible pumps power residential irrigation systems, delivering water from ponds, cisterns, and wells to lawns and gardens. Low-horsepower models provide economical operation for modest water requirements

- Pool and Spa Circulation: Submersible pumps maintain water circulation in residential pools and spas, supporting filtration and chemical treatment systems. Quiet submersible operation enables unobtrusive installation near living areas

- Rainwater Harvesting: Submersible pumps move collected rainwater from storage tanks to point-of-use locations, enabling sustainable household water management. Energy-efficient models minimize power consumption supporting off-grid operations

Industrial Applications

- Wastewater Treatment Plants: Large-capacity submersible pumps handle sewage and processed wastewater throughout treatment facilities, moving materials between treatment stages. Specialized designs manage sludge and biosolids requiring robust equipment resistant to biological and chemical attack

- Mining Operations: Heavy-duty submersible pumps manage groundwater and process water in mining pits and tunnels. Slurry pump variants handle ore slurries and tailings containing abrasive solids. Continuous operation maintains safe, dry working conditions despite substantial water inflow

- Chemical Processing: Specialized corrosion-resistant submersible pumps transfer chemicals and process fluids throughout manufacturing facilities. Temperature-resistant variants handle hot process liquids. Precise flow control supports batch processes and automated systems

- Food and Beverage Production: Sanitary-rated submersible pumps move water and process fluids in food processing facilities. Stainless steel construction meets food safety standards. Clean discharge supports product quality and regulatory compliance

- Power Generation: Submersible pumps support cooling water circulation in thermal and nuclear power plants. Large-capacity units handle substantial volumes at high pressures. Reliability and continuous operation capability are critical for uninterrupted electricity production

Environmental Applications

- Flood Management and Emergency Response: Rapid deployment of portable submersible dewatering pumps removes floodwater protecting communities and infrastructure. Emergency response teams maintain equipment reserves enabling immediate action during natural disasters. Battery-powered models operate independently of grid power during outages

- Remediation Projects: Submersible pumps move contaminated groundwater to treatment systems in environmental cleanup operations. Precise control enables proper flow rates supporting treatment effectiveness. Durable construction withstands chemical exposure in hazardous remediation environments

- Wetland and Pond Management: Controlled pumping maintains water levels in natural and artificial wetlands supporting ecosystem health. Circulation pumping prevents stagnation and supports aquatic life. Environmental restoration projects utilize submersible technology for sustainable habitat management

- Aquaculture Systems: Submersible pumps circulate and aerate water in fish farming operations, supporting water quality for healthy stock. Filter return pumps maintain biological treatment systems essential for sustainable aquaculture. Quiet operation minimizes stress on cultivated fish

Advantages of Using Submersible Water Pumps

High Efficiency

Submersible pumps convert electrical or mechanical energy to fluid movement with minimal losses. Direct water immersion eliminates suction-side friction and air handling losses reducing energy requirements by 20-40% compared to surface alternatives. Modern variable frequency drive compatibility enables operational speed adjustment optimizing efficiency across varying load conditions. This efficiency translates to lower electricity costs over the pump's operational lifespan, providing rapid return on investment through reduced utility expenses.

Low Noise Levels

Submersion in water dampens pump noise and vibration, providing nearly silent operation compared to surface-mounted alternatives. This enables installation near residential areas, offices, and sensitive environments without noise complaints. Acoustic dampening from surrounding water eliminates need for external soundproofing structures reducing installation costs. The quiet operation improves quality of life for nearby residents and workers while supporting environmental stewardship through reduced noise pollution.

Versatility

Submersible pump designs accommodate diverse applications from clean residential water supply to harsh industrial environments. Specialized variants handle sewage, slurries, chemicals, and thermal fluids. Multiple horsepower options serve applications from small residential wells to massive municipal treatment plants. Flexible electrical configurations adapt to available power infrastructure from single-phase residential service to three-phase industrial systems. This versatility enables submersible technology to serve virtually any water movement requirement.

Disadvantages of Submersible Water Pumps

While highly effective, submersible pumps have some drawbacks requiring consideration:

- Higher Initial Cost: Submersible pumps typically cost 20-40% more than equivalent surface-mounted alternatives. Sealed motor construction, specialized materials, and underwater-rated components increase manufacturing costs. However, longer lifespan and reduced maintenance often offset higher initial investment through lower total cost of ownership

- Difficult Maintenance and Repair: Accessing submerged components for service requires pump removal, potentially interrupting operations. Specialized tools and expertise may be necessary for major repairs. Some components cannot be serviced in-field requiring complete pump replacement. For critical applications, redundant systems provide backup capability during maintenance periods

- Limited Visibility into Operating Condition: Submerged operation prevents visual inspection detecting wear or developing problems. Advanced monitoring systems with sensors provide operational data, but basic models offer limited visibility. Unexpected failures can occur without warning signs if proper monitoring is not implemented

- Corrosion and Degradation Issues: Continuous water exposure causes corrosion and material degradation over time. While corrosion-resistant materials mitigate this, they increase costs. Regular inspection and preventive maintenance extend lifespan but add operational requirements. Some applications with highly corrosive fluids may require frequent equipment replacement despite material upgrades

- Power Supply Dependency: Standard electric-powered submersible pumps require reliable electrical connection. Power outages interrupt operation potentially causing hazardous conditions. Remote locations may require generator backup increasing capital and operational complexity. Solar-powered alternatives address this but at higher initial cost

- Intake Blockage Potential: Debris and sediment can block pump intakes restricting water flow. Regular strainer cleaning maintains function. In some applications with high sediment loads, frequent maintenance becomes necessary. Oversized intakes help but limit design efficiency

Tips to Overcome These Issues

- Regular Maintenance Schedule: Establish preventive maintenance programs checking pump condition quarterly or semi-annually. Clean intake strainers regularly maintaining adequate flow. Monitor electrical connections for corrosion. Professional service at manufacturer-recommended intervals identifies developing problems before failures occur

- Install Monitoring Systems: Advanced models with sensors provide real-time operational data. Automated alerts notify operators of performance changes indicating problems. Remote monitoring enables proactive management reducing unexpected failures. IoT connectivity enables predictive maintenance algorithms identifying failure risk

- Implement Redundancy: Critical applications justify multiple pumps providing backup if primary equipment fails. Automatic switchover systems maintain operation despite individual unit problems. Staged capacity enables operation with partial redundancy reducing capital costs while maintaining reliability

- Use Quality Components: Select pumps with superior corrosion-resistant materials from reputable manufacturers. Investment in higher-quality equipment extends lifespan reducing long-term costs. Specialized designs for specific applications provide better performance than general-purpose alternatives

- Ensure Proper Installation: Professional installation following manufacturer guidelines optimizes performance and reliability. Proper electrical connections, grounding, and protective devices support safe operation. Correct submersion depth and discharge configuration enable efficient operation as designed

- Plan for Power Redundancy: Install backup power systems for critical applications. Generator backup or battery-powered systems maintain operation during electrical grid outages. Solar-powered options provide sustainable backup power for remote locations

- Document Performance Data: Track operational hours, maintenance activities, and performance metrics. Historical data supports troubleshooting and identifies maintenance patterns. Documentation provides warranty claim support if equipment failures occur prematurely

Maintenance Tips for Submersible Water Pumps

To ensure the longevity of your submersible pump, follow these maintenance practices:

- Monthly Inspections: Visually inspect above-ground components including electrical connections, discharge piping, and cable connections. Check for signs of leaking, corrosion, or damage. Test automatic controls such as float switches and level sensors verifying proper operation

- Quarterly Cleaning: Remove and clean pump intake strainers removing accumulated debris and sediment. Excessive buildup restricts water flow reducing pump efficiency and creating cavitation risk. Install larger capacity strainers in applications with high sediment loads reducing cleaning frequency

- Semi-Annual Service: Conduct comprehensive electrical testing verifying motor insulation resistance and winding integrity. Check bearing condition through vibration analysis if available. Inspect seal condition for signs of water penetration. Test pump performance measuring actual flow rates and pressure against specifications

- Annual Professional Maintenance: Engage qualified technicians for detailed inspection and service. Comprehensive disassembly enables bearing and seal replacement before failure. Motor testing and restoration maximize efficiency. Complete service documentation supports warranty and performance tracking

- Preventive Component Replacement: Replace wear items such as seals and bearings on schedule before they fail. Proactive replacement prevents catastrophic failures that damage internal components. Service kits provide replacement components at reasonable cost

- Water Quality Monitoring: Regular testing of pumped water quality identifies contamination that may indicate developing equipment problems. Particulate content increase suggests wear. Chemical analysis reveals corrosive conditions requiring material upgrades

- Load Testing: Periodic performance testing compares actual operation to baseline specifications. Decreased flow rates or elevated discharge pressure indicate developing problems. Testing provides objective data supporting maintenance decisions

- Documentation and Record Keeping: Maintain detailed records of all maintenance activities, parts replacements, and performance data. Historical information supports equipment analysis and warranty claims. Documentation enables trending analysis identifying patterns in failures or performance changes

Innovations in Submersible Water Pumps

With advancing technology, modern submersible pumps offer numerous improvements enhancing performance, reliability, and sustainability:

- Smart Monitoring Systems: Integrated sensors track flow rates, pressure, temperature, and electrical parameters. IoT connectivity enables remote monitoring and control from anywhere. Predictive algorithms analyze data identifying maintenance needs before failures occur. Cloud-based platforms support performance optimization across multiple installations

- Energy-Efficient Designs: Advanced hydraulic optimization reduces energy consumption by 30-50%. Premium efficiency motors exceed industry standards for electrical-to-mechanical energy conversion. Variable frequency drive compatibility enables speed adjustment optimizing operation across varying conditions. Sustainable operation reduces carbon footprint supporting environmental goals

- Advanced Materials: Ceramic and composite impellers reduce weight enabling faster operation at equivalent power levels. Nano-coatings provide corrosion protection and reduced friction improving durability and efficiency. Self-cleaning surfaces resist fouling and scaling maintaining efficiency throughout equipment lifespan

- Renewable Energy Integration: Solar-powered submersible pumps operate independently of grid electricity. Hybrid systems combining solar and battery storage enable continuous operation. Wind-powered variants provide complementary renewable generation supporting sustainable operations

- Compact Designs: Space-efficient submersible units fit in confined installations. Lightweight composite construction enables easier installation and maintenance. Modular designs enable customization for specific applications

- Enhanced Automation: Automatic flow adjustment maintains optimal operation across varying demand. Smart level sensors prevent overfilling or inadequate supply. Integrated protection systems prevent damage from cavitation, overheating, or dry running

- Wireless Control Systems: Remote operation enables management from control centers or mobile devices. Automatic fault detection triggers alerts and corrective actions. Integration with building management systems enables coordinated water management across facilities

Choosing the Best Submersible Pump

When selecting a submersible pump, carefully consider these factors to ensure optimal performance and reliability:

- Determine Flow Requirements: Calculate average and peak water volumes requiring movement. Undersized pumps cannot meet demand while oversized equipment wastes energy and capital. Consider seasonal variations and future expansion requirements in capacity planning

- Calculate Pressure (Head) Requirements: Determine discharge elevation above water source and friction losses in piping. Pump pressure rating must overcome these requirements. Long discharge distances and significant elevation gain necessitate higher-pressure models

- Assess Fluid Characteristics: Identify whether water is clean, sewage, slurry, or specialty fluid. Specialized pump designs handle diverse applications efficiently. Clean water pumps fail quickly with sewage, while specialized designs handle harsh applications reliably

- Consider Installation Environment: Evaluate well or pit dimensions ensuring pump fits properly. Verify available electrical service (single-phase or three-phase). Assess access for installation and future maintenance. Remote locations may require energy-independent systems like solar-powered alternatives

- Evaluate Energy Efficiency: Compare power consumption across equivalent models. Energy-efficient variants reduce operational costs despite higher initial price. Variable frequency drive compatibility enables flexible operation optimizing efficiency. Calculate total cost of ownership including electricity expenses over expected lifespan

- Review Durability and Materials: Select corrosion-resistant materials appropriate for specific applications. Stainless steel provides superior durability in aggressive environments. Regular carbon steel suits clean water applications at lower cost. Specialized alloys handle chemical exposure in industrial applications

- Check Brand Reputation and Support: Established manufacturers provide reliable products and customer support. Warranty coverage and parts availability affect long-term ownership costs. Customer reviews and references provide insight into real-world performance

- Plan for Future Needs: Select pumps compatible with monitoring systems and automation. Ensure upgrade capability accommodating future technology integration. Consider scalability if applications expand requiring increased capacity

Conclusion

A submersible pump is a powerful, efficient solution for moving water in a variety of settings. From sewage pumps to dewatering pumps for construction, these versatile tools play a crucial role in modern water management. Understanding how they work and following proper maintenance practices will ensure optimal performance and longevity.

Submersible technology enables reliable water management across residential, agricultural, commercial, industrial, and environmental applications. The ability to operate submerged in diverse fluid conditions makes these pumps indispensable for modern infrastructure and operations. Whether managing groundwater in wells, handling sewage in treatment plants, removing floodwater in emergencies, or supporting industrial processes, submersible pumps provide proven, dependable solutions.

Investing in the best submersible pump tailored to your needs can make all the difference in efficiency, reliability, and long-term cost-effectiveness. Modern submersible technology combines proven performance with advanced features including smart monitoring, energy efficiency, and sustainable operations. Organizations and homeowners that select appropriate equipment, ensure proper installation, and implement comprehensive maintenance programs achieve superior results with extended equipment life and reduced operational costs.

As water management becomes increasingly critical to industrial operations, environmental protection, and community resilience, submersible pump technology will remain essential. Continued technological advancement promises even more efficient, sustainable, and intelligent water management solutions supporting global development goals and environmental stewardship objectives.