Choosing the right submersible pump for your specific needs is crucial for ensuring efficient water management, whether for domestic water supply, industrial processes, or agricultural irrigation applications. With so many options available in the market—from different power ratings and impeller designs to various materials and price points—understanding the types, features, functionalities, and selection criteria of these pumps can save you both time and money while ensuring optimal performance for years to come.

This comprehensive guide will walk you through the different types of submersible water pumps, key factors to consider during selection, proper sizing methodology, installation best practices, and tips for maintaining your pump for optimal performance, reliability, and longevity. Whether you're a homeowner installing a well pump, a farmer planning irrigation systems, or an industrial facility manager selecting process pumps, this guide provides the knowledge needed to make an informed decision that delivers value and performance.

Key Takeaways

What Is a Submersible Pump?

A submersible pump is a type of pump designed to be completely submerged in liquid, typically water, to push the liquid to the surface through discharge piping. Unlike traditional surface-mounted pumps that "pull" water through suction, submersible pumps "push" water from below, making them highly efficient, virtually noise-free, and capable of handling greater depths without cavitation issues that plague surface pumps.

How Submersible Pumps Work

Submersible pumps consist of a hermetically sealed motor directly coupled to a pump section containing an impeller. When submerged and powered on, the motor spins the impeller creating centrifugal force that pushes water upward through the pump stages and into the discharge pipe. The surrounding water provides natural cooling for the motor, preventing overheating during continuous operation.

Key Operating Principles:

Advantages Over Surface Pumps

Applications of Submersible Pumps

Submersible pumps serve diverse applications across residential, agricultural, industrial, and municipal sectors:

Residential Applications

Agricultural Applications

Industrial Applications

Municipal Applications

Commercial Applications

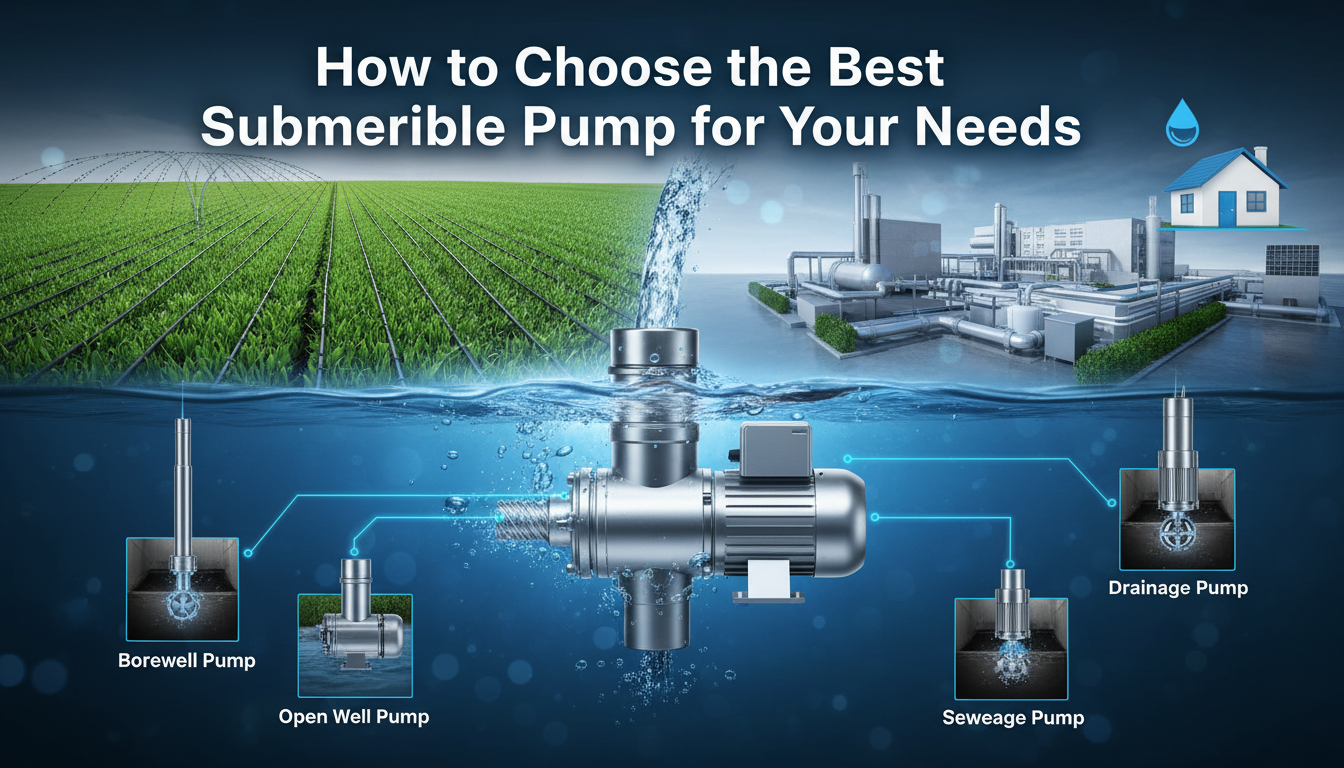

Types of Submersible Pumps

Understanding the different types of submersible pumps can help you choose the right one for your application, ensuring optimal performance, efficiency, and longevity:

1. Borewell Pumps (Deep Well Submersible Pumps)

Description: Narrow-diameter pumps (typically 4-10 inches) designed specifically for extracting groundwater from deep borewells, tube wells, and drilled wells. Multi-stage design with 5-30+ impellers stacked in series provides high head capacity necessary for lifting water from great depths.

Technical Specifications:

Ideal Applications:

Selection Considerations:

Typical Cost: $400-$2500 depending on power rating, depth capacity, and brand

2. Open Well Pumps (Shallow Well Pumps)

Description: Shorter, wider-diameter pumps suitable for open water reservoirs, dug wells, large-diameter tube wells, ponds, and tanks where water source is relatively shallow (typically under 100 feet). Feature fewer stages (2-6 typically) and larger flow capacity than borewell pumps.

Technical Specifications:

Ideal Applications:

Advantages:

Typical Cost: $300-$1500 depending on specifications

3. Sewage Pumps

Description: Robust pumps designed for pumping sewage and wastewater containing solid waste, toilet paper, and other materials. Feature non-clog impeller designs (vortex, channel, or semi-open) passing solids 2-3 inches diameter without blockage.

Technical Specifications:

Ideal Applications:

Key Features:

Typical Cost: $400-$3000 depending on capacity and features

4. Slurry Pumps

Description: Heavy-duty industrial pumps designed to handle thick, slurry-like liquids containing high concentrations of suspended solids (40-70% by weight). Constructed with hardened materials resisting extreme abrasion from mineral particles, sand, and other abrasive materials.

Technical Specifications:

Ideal Applications:

Special Features:

Typical Cost: $1500-$20,000+ depending on size and materials

5. Cutter Pump Sewage

Description: Specialized sewage pumps equipped with hardened steel cutting blades that grind solid particles into fine slurry (3-10mm) before pumping. Also called grinder pumps or macerator pumps, enabling pumping through smaller diameter pipes (1.25-2 inches vs 3-4 inches) over longer distances.

Technical Specifications:

Ideal Applications:

Advantages:

Typical Cost: $1500-$6000 for residential/commercial units

6. Submersible Drainage Pump

Description: Designed specifically for draining flood water, surface water accumulation, excess liquid from construction sites, basements, and other areas requiring rapid water removal. Handle clean to moderately dirty water with particles up to 1-1.5 inches.

Technical Specifications:

Ideal Applications:

Key Features:

Typical Cost: $150-$2000 depending on capacity

Comparison Table: Pump Types by Application

| Borewell Pumps | Deep well groundwater extraction | Clean water only | 0.5-25 HP | $400-$2500 | Open Well Pumps | Shallow wells, ponds, reservoirs | Small debris | 1-10 HP | $300-$1500 | Sewage Pumps | Wastewater with solid waste | 2-3 inch solids | 0.5-5 HP | $400-$3000 | Slurry Pumps | Abrasive industrial slurries | 70% solids, 100mm | 3-200+ HP | $1500-$20,000+ | Cutter Pumps | Sewage grinding, pressure sewers | Grinds all solids | 1-10 HP | $1500-$6000 | Drainage Pumps | Flood water, surface drainage | 0.5-1.5 inch solids | 0.5-10 HP | $150-$2000 |

Factors to Consider When Choosing a Submersible Pump

When selecting the best submersible pump, carefully consider the following factors to ensure optimal performance, efficiency, and longevity:

1. Purpose of the Pump

Identifying the specific application is the first and most important step in pump selection, as different applications have vastly different requirements:

Domestic Water Supply

Requirements:

Recommended Pump: Stainless steel borewell pump, 0.75-1.5 HP, multi-stage design

Agricultural Irrigation

Requirements:

Recommended Pump: Cast iron or stainless steel pump, 1.5-5 HP, designed for outdoor installation

Industrial Applications

Requirements:

Recommended Pump: Industrial-grade pump with appropriate materials, 5-50+ HP, three-phase power

Wastewater Management

Requirements:

Recommended Pump: Sewage pump with non-clog impeller, 0.75-2 HP, cast iron or stainless construction

2. Flow Rate and Discharge Capacity

Calculating required flow rate (measured in gallons per minute - GPM, or liters per minute - LPM) is critical for proper pump sizing. Undersizing causes inadequate water supply; oversizing wastes money and energy.

Residential Flow Rate Calculation

Method 1: Fixture Count Method

Calculation: Sum GPM for fixtures likely to run simultaneously, add 20% safety factor

Example: 2 bathrooms (2 showers at 4 GPM = 8 GPM) + kitchen (5 GPM) + washer (4 GPM) = 17 GPM × 1.2 = 20 GPM required

Method 2: Per-Person Method

Agricultural Flow Rate Calculation

Drip Irrigation:

Sprinkler Irrigation:

Flood Irrigation:

Commercial/Industrial Calculation

Based on specific process requirements, equipment specifications, and peak demand analysis. Consult with engineers for accurate sizing of large systems (typically requiring professional hydraulic calculations considering simultaneous use factors, diversity factors, and future expansion).

3. Motor Efficiency

Motor efficiency directly impacts operating costs and environmental footprint. High-efficiency motors cost 20-30% more initially but save 15-25% on electricity, typically paying back within 2-4 years through reduced energy consumption.

Motor Efficiency Classifications

Standard Efficiency (IE1):

High Efficiency (IE2):

Premium Efficiency (IE3):

Super Premium Efficiency (IE4):

Energy Cost Calculation Example

Scenario: 2 HP pump, 2000 hours/year operation, $0.12/kWh electricity

If IE3 motor costs $150 more than IE1, payback period = $150 ÷ $51/year = 3 years

4. Material and Durability

Material selection significantly impacts pump longevity, maintenance requirements, and total cost of ownership. Match materials to water quality and operating environment:

Cast Iron

Characteristics:

Advantages:

Disadvantages:

Best For: Clean water with neutral pH, budget-conscious residential installations, standard well water applications

Expected Life: 8-12 years with proper maintenance in suitable water conditions

Stainless Steel (SS304)

Characteristics:

Advantages:

Disadvantages:

Best For: Potable water systems, corrosive water (low/high pH), residential installations valuing longevity, food industry applications

Expected Life: 10-15 years in standard residential service

Stainless Steel (SS316)

Characteristics:

Advantages:

Disadvantages:

Best For: Coastal installations, industrial chemicals, water treatment plants, high-chloride water, maximum longevity priority

Expected Life: 15-20+ years even in aggressive conditions

Bronze and Brass

Characteristics:

Best For: Impellers, wear rings, bushings in quality pumps; potable water systems; residential applications

Expected Life: 12-18 years with proper water chemistry

Thermoplastic (Polypropylene, PVDF)

Characteristics:

Advantages:

Disadvantages:

Best For: Extremely corrosive water, chemical transfer, temporary installations, budget applications accepting shorter life

5. Pump Size and Installation Depth

Physical pump dimensions and required installation depth critically affect system design and performance:

Pump Diameter Considerations

Borewell Applications:

Open Well/Sump Applications:

Installation Depth Requirements

Minimum Submersion Depth:

Maximum Installation Depth:

Optimal Installation Depth:

How to Match a Pump to Your Needs

Assess Your Water Source

Understanding your water source characteristics is fundamental to proper pump selection:

Well Type and Characteristics

Borewell/Tube Well:

Example Assessment:

Open Well/Pond Characteristics

Assessment Factors:

Water Quality Analysis

Critical Water Quality Parameters:

Choose the Right Motor Capacity

Matching motor horsepower (HP) to application ensures optimal performance and efficiency:

Residential Applications

| Small home (1-2 people) | 0.5-0.75 HP | 6-10 GPM | 50-150 feet | Medium home (3-4 people) | 1 HP submersible pump | 10-15 GPM | 100-250 feet | Large home (5-6 people) | 1.5 HP submersible pump | 15-25 GPM | 150-300 feet | Estate home (7+ people) | 2-3 HP | 25-40 GPM | 200-400 feet |

Agricultural Applications

| Small garden/orchard | 1-1.5 HP | 10-20 GPM | 1-2 acres drip | Medium farm irrigation | 1.5-3 HP | 20-50 GPM | 3-8 acres sprinkler | Large agricultural operation | 5-10 HP | 50-150 GPM | 10-25 acres | Commercial farming | 10-25 HP | 150-500 GPM | 25-100+ acres |

Industrial Applications

| Light industrial | 3-5 HP | 50-100 GPM | Process water, cooling | Medium industrial | 5-15 HP | 100-300 GPM | Manufacturing, processing | Heavy industrial | 15-50 HP | 300-1000 GPM | Large facilities, mining | Municipal/major industrial | 50-200+ HP | 1000-10,000+ GPM | Water plants, large operations |

Motor Selection Formula

Hydraulic Power Required (HP) = (Flow Rate × Total Head × Specific Gravity) / (3960 × Pump Efficiency)

Example Calculation:

Submersible Pump Maintenance Tips

Maintaining your submersible water pump ensures optimal performance, extends lifespan significantly (often doubling service life from 7-8 years to 15+ years), and prevents costly emergency failures.

1. Routine Maintenance

Monthly Tasks (15-20 minutes)

Quarterly Tasks (1-2 hours)

Annual Major Maintenance (4-8 hours or professional service)

2. Inspect for Damage

Warning Signs Requiring Immediate Attention

Performance Issues:

Noise and Vibration:

Water Quality Changes:

Electrical Problems:

3. Seasonal Checklist

Spring Preparation (April-May)

Summer Monitoring (June-August)

Fall Preparation (September-November)

Winter Protection (December-March)

Popular Brands and Models of Submersible Pumps

Here are some trusted brands offering high-quality submersible pumps with proven reliability and comprehensive support:

Premium International Brands

1. Grundfos (Denmark)

2. Franklin Electric (USA)

3. Pedrollo (Italy)

Quality Indian Manufacturers

| CRI Pumps | Energy-efficient dewatering pumps | Borewell pumps, openwell pumps, industrial pumps | ₹8,000-₹50,000 | Crompton | Reliable submersible sewage pumps | Residential submersibles, sewage pumps, agricultural pumps | ₹6,000-₹40,000 | Kirloskar Brothers | Comprehensive range, 130+ years experience | Complete pump solutions, industrial to domestic | ₹10,000-₹80,000 | Torren/Unnati Pumps | Durable slurry pumps for industrial use | Industrial pumps, slurry pumps, customized solutions | ₹15,000-₹2,00,000 | V-Guard | Value-oriented residential pumps | Borewell pumps, openwell pumps, budget-friendly options | ₹5,000-₹25,000 | Havells | Consumer electronics quality applied to pumps | Residential submersibles, energy-efficient models | ₹7,000-₹35,000 |

Brand Selection Criteria

Consider When Choosing Brand:

Environmental and Safety Considerations

Energy Efficiency

Energy efficiency impacts both operating costs and environmental footprint. Submersible pumps represent significant electrical loads, often operating thousands of hours annually:

Efficiency Optimization Strategies

1. High-Efficiency Motors

2. Proper Pump Sizing

3. Variable Speed Drives (VFD)

4. Maintenance for Efficiency

Carbon Footprint Reduction

Calculating Environmental Impact:

Renewable Energy Integration:

Safe Installation

Proper installation ensures safety, performance, and longevity while preventing hazards:

Electrical Safety Requirements

Critical Electrical Considerations:

Well and Pump Installation Safety

Installation Best Practices:

Regulatory Compliance

Required Permits and Standards:

Conclusion

Choosing the right submersible pump involves systematically assessing your specific needs including application type, required flow rates, and total dynamic head; understanding the different types of pumps available from borewell pumps for deep wells to sewage pumps for wastewater management; and carefully considering key factors like motor capacity (matching horsepower to demand), material durability (selecting construction appropriate for water quality), and efficiency ratings (balancing initial cost against long-term operating expenses).

Whether you need a submersible sewage pump for residential basement bathroom ejector applications serving household wastewater needs, or a dewatering pump for demanding industrial applications requiring high-volume water removal from construction sites or mining operations, making an informed decision based on comprehensive analysis ensures efficient performance delivering adequate flow and pressure, long-term reliability minimizing failures and downtime, and significant savings through reduced energy consumption and maintenance costs over the pump's 10-15+ year expected service life.

Remember that proper pump selection extends beyond initial purchase price to encompass total cost of ownership including energy consumption (typically 40-50% of lifecycle costs), maintenance expenses (20-30% of lifecycle costs), and replacement/repair costs. A quality pump from reputable manufacturers like Grundfos, Franklin Electric, CRI, or Crompton combined with professional installation ensuring code compliance and optimal setup, along with systematic maintenance following manufacturer recommendations and seasonal best practices, provides decades of reliable service protecting your investment.

For reliable and high-quality options backed by comprehensive warranties and technical support, explore products from trusted submersible pump manufacturers and choose one that fits your specific requirements regarding power rating, flow capacity, head capability, material construction, and budget constraints. Consult with experienced pump dealers, professional well drillers, or hydraulic engineers for complex applications ensuring proper sizing and optimal system design.

The investment you make today in selecting the right submersible pump, installing it properly, and maintaining it systematically pays dividends for years to come through reliable water supply meeting your household, agricultural, or industrial needs; reduced operating costs from energy-efficient operation; minimal downtime from preventive maintenance; and peace of mind knowing your water management system operates safely and dependably 24 hours a day, 365 days a year.