Complete Guide to Choosing the Right Submersible Pump for Your Application

Choosing the right submersible pump is critical for efficient water management in various applications, including residential, agricultural, and industrial settings. The proper selection of a submersible pump 1 hp, submersible pump 1.5 hp, or a submersible water pump ensures optimal performance, cost-efficiency, and long-term longevity for your water management system. In this comprehensive guide, we will discuss the key factors to consider when selecting a submersible pump, including flow rate, head height, and specific use cases such as dewatering pumps for construction, sewage sludge pumps, and various industrial applications.

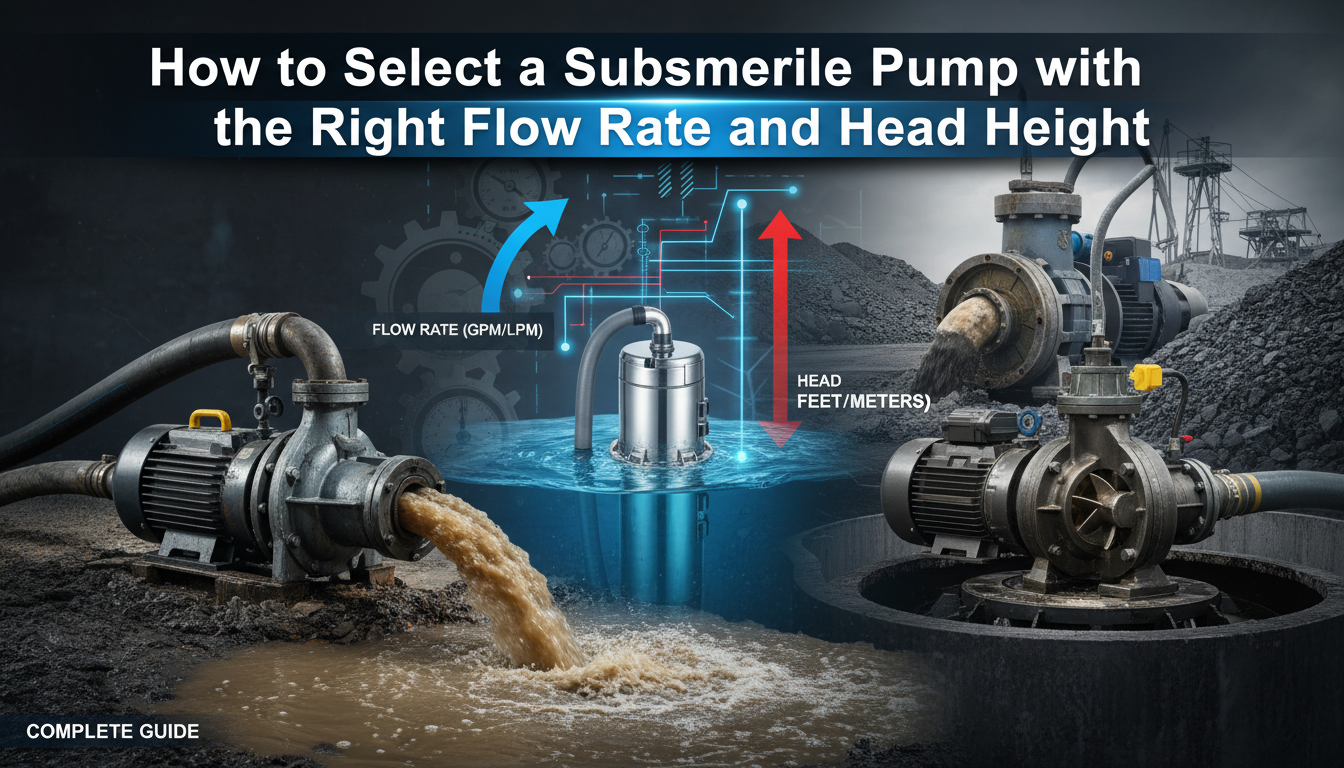

Understanding Flow Rate and Head Height: Critical Specifications for Submersible Pumps

Before selecting a submersible pump for your application, it is absolutely important to understand two critical specifications that determine pump performance and suitability. Flow rate refers to the volume of water or liquid that a submersible pump can move per unit of time, typically measured in gallons per minute or liters per minute. Understanding the required flow rate for your submersible pump application ensures you select a model with adequate capacity to meet your water management needs.

Head height, also called total dynamic head, represents the vertical distance that a submersible pump must lift water against gravity. This critical specification includes the vertical height the submersible pump must lift water, plus resistance from friction in pipes and fittings. Both flow rate and head height factors work together to determine the overall power requirements and suitability of a submersible pump for your specific needs and application requirements.

Types of Submersible Pumps and Their Applications

1. Submersible Water Pump for General Applications

A submersible water pump is ideal for draining water from flooded basements, residential wells, or water storage tanks efficiently. Submersible water pumps are designed to operate underwater and provide efficient pumping action with minimal noise during operation. These versatile submersible water pumps work well for clear water applications and are commonly used in residential and agricultural settings where reliable water management is essential.

2. Dewatering Pump for Construction and Industrial Sites

A dewatering pump is commonly used in construction sites, mining operations, and flood-prone areas to remove excess water quickly and efficiently. There are different types of dewatering pumps available, including the dewatering pump 1 hp for smaller applications and the dewatering pump submersible for varying capacities and depths. Each dewatering pump model is engineered for specific water volumes and operating conditions. Dewatering pumps for construction are specifically designed to handle the demanding requirements of active job sites and challenging environments.

3. Sewage Pump for Wastewater Management

A sewage pump is essential for handling wastewater containing solids and is a critical component of proper waste management systems. These specialized sewage pumps are commonly used in homes, municipal sewage systems, and industrial waste treatment plants. Sewage pumps are engineered to handle the unique challenges of wastewater containing solid particles and organic matter. For properties dealing with higher solid content, sewage sludge pumps provide enhanced capability for handling thicker waste materials.

4. Slurry Pump for Heavy Industrial Applications

A slurry pump is specifically designed to handle highly abrasive fluids containing solid particles and is essential in demanding industrial environments. Slurry pumps are widely used in mining operations, dredging projects, and various industrial applications requiring the movement of thick liquid-solid mixtures. Leading slurry pump manufacturers provide models with enhanced durability specifically engineered for heavy-duty operations and abrasive material handling.

Key Factors to Consider When Selecting a Submersible Pump

Application Type and Liquid Characteristics

Different submersible pump types are designed for specific applications and liquid characteristics. For clean water applications, a standard submersible water pump is appropriate for your needs. For wastewater containing solids, a sewage pump or sewage sludge pump is necessary. For extremely abrasive or high-solid-content applications, slurry pumps from specialized slurry pump manufacturers provide the durability needed. Understanding your specific application ensures you select the right submersible pump for optimal performance.

Power Requirements and Horsepower

Submersible pumps are available in various horsepower ratings, with common options including the submersible pump 1 hp for smaller applications and the submersible pump 1.5 hp for larger systems. The appropriate horsepower for your submersible pump depends on your required flow rate, head height, and the specific liquid you're pumping. Higher horsepower submersible pumps provide greater capacity but consume more energy, so choosing the right pump rating balances performance and operational cost.

Operating Environment and Depth

The operating environment where your submersible pump will function is crucial to your selection process. Construction sites, mining operations, and flood-prone areas require specialized submersible pumps designed for those conditions. The maximum depth at which your submersible pump must operate also affects model selection. Understanding your operating environment ensures the submersible pump you select can withstand the specific conditions and demands of your application.

Selecting from Reputable Submersible Pump Manufacturers

Investing in high-quality submersible pumps from reputable manufacturers ensures long-term efficiency and reliability for your water management system. Specialized slurry pump manufacturers design pumps specifically for abrasive applications. Sludge pump manufacturers create pumps engineered for handling thick, viscous waste materials. Dewatering pump manufacturers develop pumps optimized for removing water in construction and industrial settings. Each type of manufacturer brings specialized expertise to pump design and engineering.

Conclusion: Make an Informed Submersible Pump Selection

Selecting the right submersible pump involves careful consideration of flow rate, head height, application type, and environmental factors. Whether you need a dewatering pump for construction projects, a slurry pump for mining operations, or a submersible sump pump for residential water management, understanding these critical factors will help you make an informed decision.

Investing in high-quality submersible pumps from reputable slurry pump manufacturers, sludge pump manufacturers, or dewatering pump manufacturers ensures that your water management system operates efficiently and reliably. By taking time to properly assess your specific needs and selecting the appropriate submersible pump, you ensure optimal performance, cost-effectiveness, and long-term reliability for your water management application.