Industrial pump pressure ratings are fundamental specifications that determine whether a pump can safely handle the operating conditions of your application. Understanding ANSI pressure classes and pressure standards is critical for engineers, procurement managers, and facility operators who need to select the right equipment for chemical processing, wastewater treatment, manufacturing, and dozens of other industrial applications.

According to the American Society of Mechanical Engineers (ASME), improper pressure rating selection is one of the leading causes of pump failures in industrial settings. In this comprehensive guide, we'll explore what pressure ratings mean, how ANSI classification systems work, and how to use this knowledge to make better pump selection decisions.

What Are Pump Pressure Ratings?

Pump pressure ratings indicate the maximum pressure that a submersible pump or centrifugal pump can safely withstand during normal operation. These ratings account for the pump's design, materials, construction methods, and how components like casings, flanges, and seals are assembled.

The American National Standards Institute (ANSI) established these standardized ratings to provide a common language for pump specifications across industries and manufacturers.

Why Pressure Ratings Matter

Selecting a pump with inadequate pressure ratings can lead to catastrophic failures including:

Key Principle: A pump's pressure rating must always exceed your system's maximum operating pressure, typically with a safety margin of 10-20% to account for pressure spikes and transient conditions.

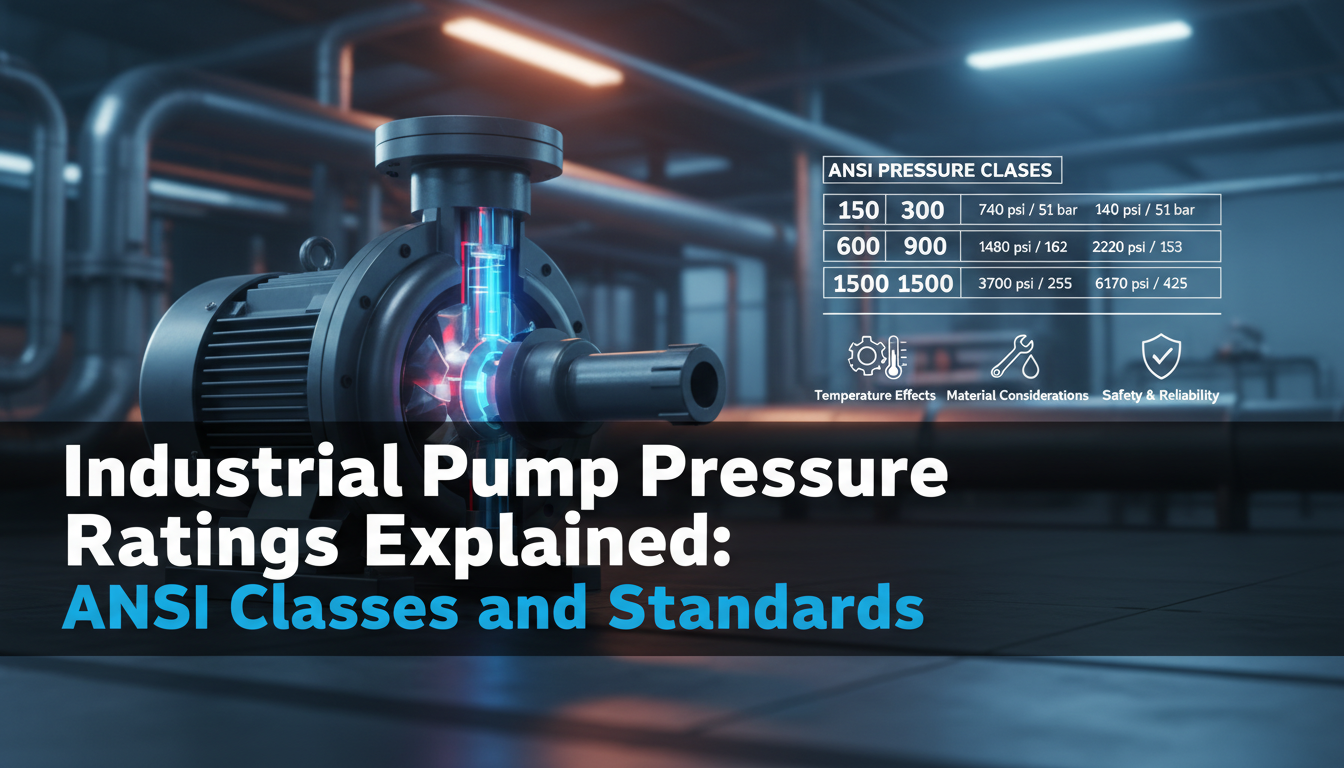

Understanding ANSI Pump Pressure Classes

The American National Standards Institute (ANSI) establishes standardized pressure classifications for industrial pumps, primarily through standards like ANSI B16.5 for flange ratings. These classifications simplify pump selection by grouping similar pressure capabilities into designated "classes."

Understanding ANSI pressure classifications helps facility managers compare equipment from different manufacturers using a common standard.

Standard ANSI Pressure Classes

The most common ANSI pressure classes for industrial pumps include:

| 150 | 285 psi | 19.6 bar | Low-pressure circulation, HVAC systems, general industrial flow | 300 | 740 psi | 51 bar | Medium-pressure applications, chemical transfer, refinery processes | 600 | 1,480 psi | 102 bar | High-pressure chemical processing, pressurized systems, oil and gas | 900 | 2,220 psi | 153 bar | Very high-pressure applications, specialized industrial processes | 1500 | 3,700 psi | 255 bar | Extreme pressure applications, specialized manufacturing | 2500 | 6,170 psi | 425 bar | Ultra-high-pressure systems, specialized equipment |

Important Note: ANSI pressure classes are standardized ratings that apply to flange connections and pump casings. The actual maximum operating pressure of your specific pump depends on its design, materials, and the combined ratings of all components in the system.

Pressure Ratings and Material Considerations

It's crucial to understand that pressure ratings can vary depending on the material of construction and operating temperature. Different materials have different strength characteristics at elevated temperatures. The material selected for your pump significantly impacts its pressure capability.

Material Impact on Pressure Ratings

Common pump materials and their typical applications:

Temperature Effects on Pressure Ratings

As operating temperature increases, material strength typically decreases. ANSI standards provide derating factors for different materials at elevated temperatures. For example, a Class 300 carbon steel pump rated for 740 psi at ambient temperature may have a reduced rating at 500°F.

Temperature Derating Principle: Always verify your pump's pressure rating at the actual operating temperature of your system. Temperature-adjusted ratings are typically lower than room-temperature ratings. Request pressure-temperature curves from manufacturers for accurate ratings.

Key Industrial Pump Standards Beyond ANSI

While ANSI is the dominant standard in North America, several other important standards govern industrial pump specifications and pressure ratings:

API Standards (American Petroleum Institute)

API 610 covers centrifugal pumps for petroleum and chemical industries, including detailed pressure and temperature specifications, material selections, and performance requirements. This standard is critical for oil and gas applications and ensures equipment meets industry-specific safety requirements.

ISO Standards (International Organization for Standardization)

ISO 5198 provides requirements for centrifugal pumps and ISO 4413 covers hydraulic fluid power systems. These standards ensure global compatibility and are particularly important for international equipment procurement and cross-border operations.

ASME Standards (American Society of Mechanical Engineers)

ASME B16.5 covers pipe flanges and flanged fittings, which directly impact pressure ratings. ASME Boiler and Pressure Vessel Code (BPVC) applies to certain pump applications where pressure vessels are involved. Understanding ASME standards ensures compliance and safety in regulated industries.

AWWA Standards (American Water Works Association)

AWWA standards are specific to water and wastewater applications, defining pump requirements for public water systems, including pressure ratings, performance, and reliability specifications. Essential for sewage pump and municipal dewatering pump applications.

Selecting the Right Pressure Rating for Your Application

Choosing the correct ANSI pressure class requires careful analysis of your system's operating conditions. This systematic approach ensures safety and optimal performance:

Step 1: Determine Your Maximum Operating Pressure

Calculate the highest pressure your system will experience under normal operation, including:

Document this pressure in both PSI and bar formats for clarity.

Step 2: Add a Safety Margin

Industry best practice recommends a safety margin of 10-20% above your maximum operating pressure. This accounts for:

Calculation Example: If maximum operating pressure is 500 psi, add 10-20% safety margin (50-100 psi) to arrive at 550-600 psi minimum pump rating.

Step 3: Consider Temperature Effects

Determine your system's maximum operating temperature and verify that the pump's pressure rating is maintained at that temperature. Request temperature-derated pressure ratings from manufacturers. This is critical for accurate equipment selection.

Step 4: Account for Material Requirements

If your application involves corrosive chemicals, hot fluids, or abrasive materials, select a pump material that maintains adequate strength at your operating conditions. Material compatibility with your fluid is essential.

Step 5: Verify All Components

Remember that the pump pressure rating is only as strong as the weakest component in your system. Verify that:

Consequences of Incorrect Pressure Ratings

Selecting a pump with insufficient or inappropriate pressure rating can have serious consequences for safety and operations:

Undersized Pressure Ratings

Oversized Pressure Ratings

The goal is to match your pump pressure rating precisely to your system requirements—neither undersized nor over-engineered.

Monitoring Pressure Ratings During Equipment Life

Pressure ratings don't change after installation, but the condition of your pump does. Regular maintenance helps ensure your equipment continues to perform safely within its rated specifications:

Conclusion: Mastering ANSI Pump Pressure Ratings

Understanding ANSI pump pressure ratings and industrial pump standards is essential for safe, efficient, and reliable pump operation. ANSI classes provide a standardized way to compare pressure capabilities across manufacturers, but the most important principle is matching your pump's rating to your specific application requirements.

Whether you're working with Class 150 low-pressure circulation pumps or Class 2500 ultra-high-pressure systems, always verify that your selected pump maintains adequate pressure rating at your actual operating temperature and conditions.