Introduction

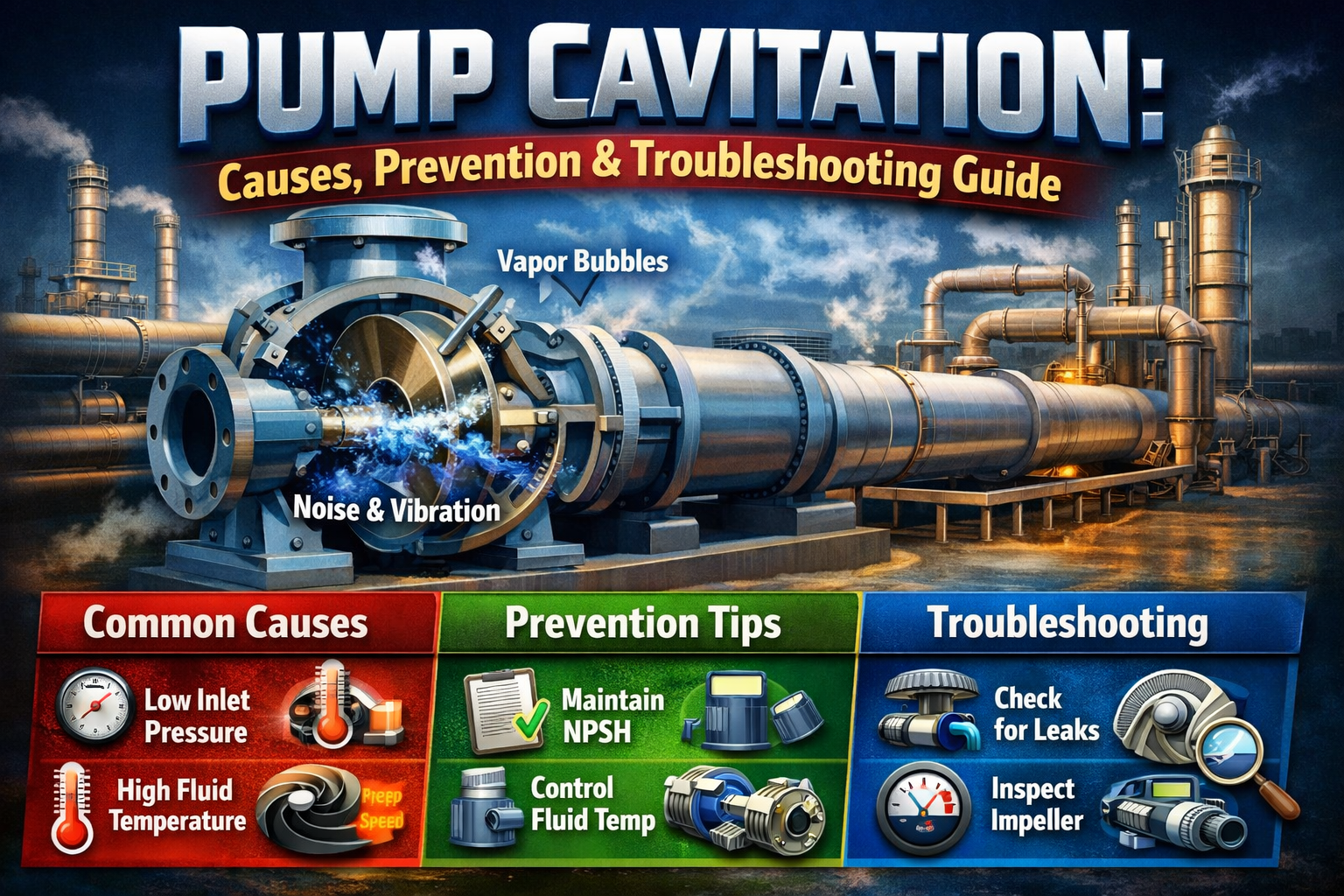

Pump cavitation is one of the most damaging phenomena affecting submersible pumps and industrial pumping systems. This destructive process occurs when vapor bubbles form and collapse within the pump, causing erosion, noise, vibration, and catastrophic equipment failure if left unchecked.

According to the American Society of Mechanical Engineers (ASME), cavitation is responsible for millions of dollars in equipment damage annually across industrial facilities. Understanding cavitation—its causes, effects, and prevention strategies—is essential for anyone responsible for maintaining dewatering pumps, sewage pumps, or any pressurized pumping system.

In this comprehensive guide, we'll explore what cavitation is, why it happens, how to recognize it, and most importantly, how to prevent it from damaging your equipment.

What Is Pump Cavitation?

Pump cavitation is a fluid dynamics phenomenon where vapor bubbles form inside the pump when the local pressure drops below the vapor pressure of the liquid being pumped. These bubbles collapse when they reach areas of higher pressure, creating shock waves that damage pump components.

The Cavitation Process: Step-by-Step

Step 1: Pressure Drop – As liquid enters the pump's eye (suction side), velocity increases and pressure decreases

Step 2: Vapor Formation – If pressure drops below the liquid's vapor pressure, the liquid vaporizes forming bubbles

Step 3: Bubble Transport – These vapor bubbles travel through the pump with the fluid

Step 4: Bubble Collapse – When bubbles reach higher-pressure areas in the discharge section, they collapse violently

Step 5: Shock Waves – The collapse creates intense shock waves that damage nearby surfaces at speeds exceeding the speed of sound

Result: Surface erosion, material loss, and progressive component degradation

Why Cavitation Matters

Cavitation causes several serious problems:

Understanding NPSH: The Key to Cavitation Prevention

Net Positive Suction Head (NPSH) is the critical parameter for preventing cavitation. Understanding this concept is essential for proper pump operation.

What Is NPSH?

NPSH is the absolute pressure at the pump inlet relative to the liquid's vapor pressure. It represents the energy available at the pump suction to prevent cavitation.

NPSH Formula:

NPSH Available (NPSHa) = Atmospheric Pressure + Static Suction Head - Friction Loss - Vapor Pressure

Where:

- Atmospheric Pressure ≈ 34 feet (10.3 meters) for water at sea level

- Static Suction Head = vertical distance from source to pump inlet

- Friction Loss = resistance in suction lines

- Vapor Pressure = pressure at which liquid vaporizes (varies by temperature)

NPSH Required vs. NPSH Available

Two types of NPSH must be understood:

Critical Rule: NPSHa must always be greater than NPSHr by at least 3 feet (1 meter) safety margin. If NPSHa < NPSHr, cavitation will occur.

Temperature Effects on Vapor Pressure

Temperature dramatically affects cavitation risk:

| 32°F (0°C) | 0.08 psia | Very Low | 68°F (20°C) | 0.36 psia | Low | 104°F (40°C) | 0.88 psia | Moderate | 140°F (60°C) | 1.95 psia | High | 176°F (80°C) | 3.85 psia | Very High | 212°F (100°C) | 14.7 psia | Extreme |

Key Insight: As temperature increases, vapor pressure increases dramatically. Pumping hot water or warm liquids significantly increases cavitation risk. A pump that operates fine at 68°F may cavitate severely at 140°F even under identical pressure conditions.

Common Causes of Pump Cavitation

Cause 1: Excessive Suction Lift

Suction lift occurs when the liquid source is below the pump inlet. Each foot of lift reduces available NPSH:

Cause 2: Restricted Suction Lines

Friction losses in suction lines reduce available NPSH:

Cause 3: High Operating Speed

Higher pump speeds increase cavitation risk:

Cause 4: High Fluid Temperature

As we saw in the table above, temperature dramatically increases vapor pressure:

Cause 5: High Altitude Operation

Atmospheric pressure decreases at higher elevations:

Cause 6: Air Leaks in Suction Line

Even small air leaks can trigger cavitation:

Cause 7: Improper Pump Priming

Poorly primed pumps introduce air into the system:

Recognizing Cavitation in Your Pump

Early detection of cavitation is critical. Watch for these warning signs:

Audible Indicators

Visual Indicators

Performance Indicators

Cavitation Prevention Strategies

Strategy 1: Optimize System Design

Flooded Suction Advantage: Position the pump below the source liquid level (flooded suction) instead of lifting from below. This provides atmospheric pressure assistance instead of requiring lift.

Suction Line Design: Minimize friction losses in suction piping:

Strategy 2: Maintain Adequate Suction Pressure

Strategy 3: Control Operating Speed

Strategy 4: Regular Maintenance

Strategy 5: Select Appropriate Pump Type

Troubleshooting Cavitation Problems

If you suspect cavitation, follow this troubleshooting procedure:

Step 1: Confirm Cavitation Is Occurring

Step 2: Measure Current Operating Conditions

Step 3: Calculate NPSH Available

Example Calculation:

Atmospheric Pressure: 14.7 psia (sea level)

Static Suction Head: -5 feet (pump 5 feet above source)

Suction Line Friction Loss: -2 feet

Vapor Pressure at 80°F: -0.5 psia

NPSHa = 14.7 - 5 - 2 - 0.5 = 7.2 feet

If pump requires NPSHr = 10 feet, cavitation will occur (7.2 < 10)

Step 4: Identify Root Cause

Based on your measurements, identify the primary cause:

Step 5: Implement Corrective Action

Address the root cause using strategies from the Prevention section above.

Step 6: Verify Solution

Cavitation in Different Pump Types

Submersible Pumps

Submersible pumps are generally resistant to cavitation because they operate with flooded suction (they're submerged). However, cavitation can still occur if:

Dewatering Pumps

Dewatering pumps often experience cavitation because they're used with suction lift (source below pump). Prevention requires:

Sewage Pumps

Sewage pumps can experience cavitation if discharge becomes restricted. Cutter pump operation can create pressure fluctuations that trigger cavitation.

Slurry Pumps

Slurry pumps are particularly prone to cavitation because:

Equipment Damage from Untreated Cavitation

If cavitation continues unchecked, progressive damage occurs:

Stage 1: Early Cavitation (Hours to Days)

Stage 2: Moderate Cavitation (Days to Weeks)

Stage 3: Severe Cavitation (Weeks to Months)

Stage 4: Complete Failure

Cavitation Prevention Checklist

Installation Design:

Operating Conditions:

Maintenance:

Cavitation in High-Performance Applications

High-Temperature Applications

Pumping hot water or process fluids dramatically increases cavitation risk:

High-Altitude Operation

At elevations above sea level, cavitation risk increases significantly:

Demanding Industrial Applications

Slurry and abrasive applications require extra cavitation protection:

Conclusion: Protecting Your Pump from Cavitation

Pump cavitation is a preventable problem. Understanding its causes, recognizing early warning signs, and implementing proven prevention strategies can protect your equipment and extend its operating life significantly.

Remember these key principles:

Get Expert Cavitation Prevention Guidance

If you're concerned about cavitation risk in your system, The Flow Chem Pumps can help. Our technical team specializes in:

Concerned about cavitation in your system? Contact our experts for cavitation risk assessment and prevention strategies.

Related Resources

Learn More About Pump Systems & Maintenance:

About The Flow Chem Pumps

The Flow Chem Pumps provides comprehensive pump solutions for residential, commercial, and industrial applications. We specialize in equipment selection that prevents common problems like cavitation while maximizing performance and efficiency.

Our technical expertise includes:

We help engineers and facility managers select equipment that performs reliably without experiencing cavitation or other operational problems. Visit The Flow Chem Pumps to request expert technical consultation for your pumping application.