Sewage Pump Troubleshooting Guide: Identifying and Solving Common Problems

A sewage pump is a critical component in any wastewater management system. Its primary function is to transport sewage from one location to another, typically from homes or buildings to a septic system or municipal sewer facility. However, like any mechanical device, these pumps can encounter various issues that compromise their performance and reliability. Whether you're dealing with a submersible sewage pump or a cutter pump sewage system, knowing how to troubleshoot common problems is key to maintaining system efficiency and preventing costly repairs.

This comprehensive guide is designed to help you understand and solve the most frequent issues encountered with sewage pumps, including submersible pumps, dewatering pumps, and slurry pumps. By learning how to identify these problems early, you can ensure the longevity of your sewage pump and avoid serious disruptions to your wastewater system.

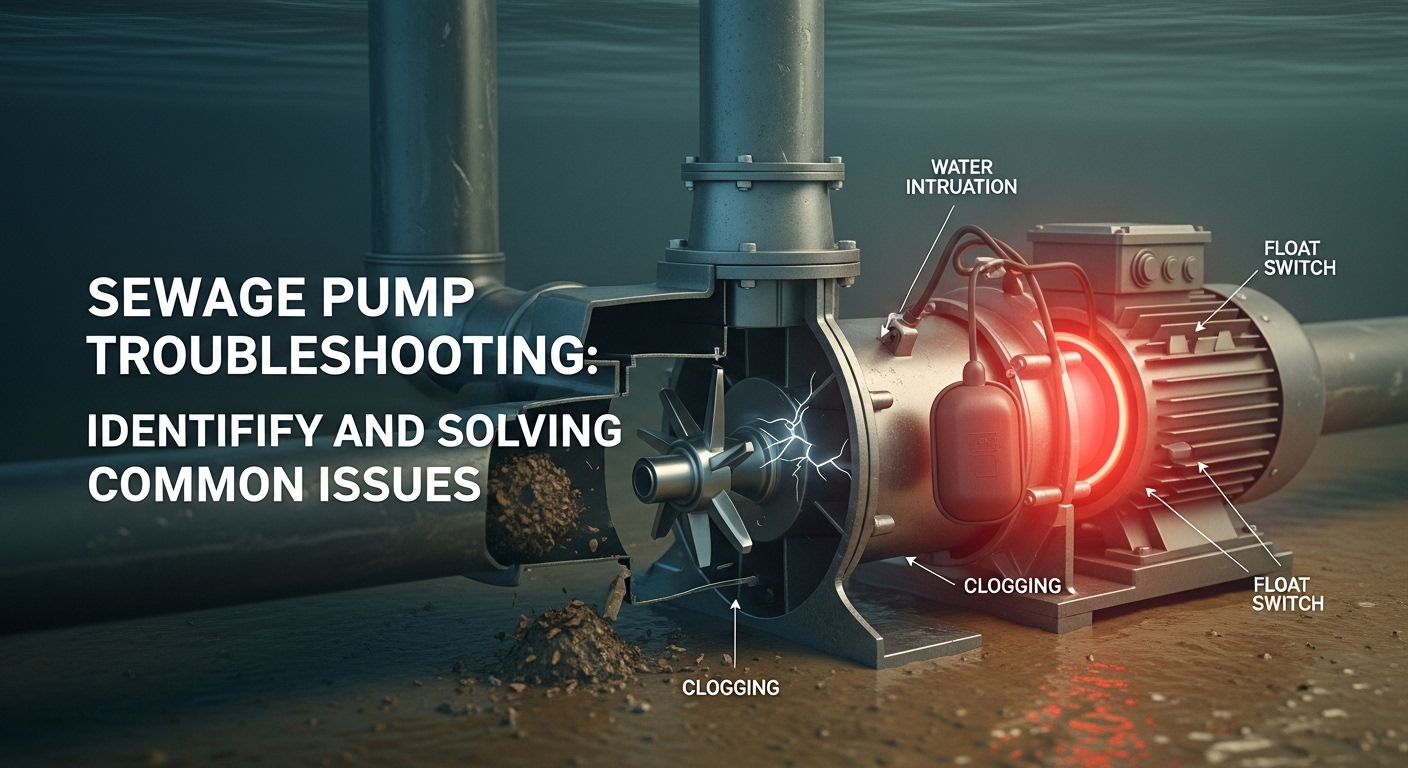

Clogging Issues in Sewage Pumps

Submersible sewage pumps are prone to clogging due to the nature of the materials they handle daily. This is especially common when dealing with sludge pumps or slurry pumps, which transport thick, viscous liquids containing various solids. Clogging often results from an accumulation of debris, wipes, or other foreign objects that enter the sewage system.

Symptoms of clogging in your sewage pump include reduced water flow and discharge from the system indicating blockage development. Unusual grinding or rattling sounds from the sewage pump suggest debris caught in the impeller. Frequent pump shutdowns or failure to activate when water levels rise suggest clogging preventing normal operation. Water backup into the facility indicates the sewage pump cannot discharge properly. Increased power consumption by the pump motor suggests it's working harder against a clog. Rising water levels in the sump or tank despite normal sewage input indicate discharge line blockage.

Solutions to prevent clogs include regular maintenance and proper system management. Installing a cutter pump or submersible slurry pump with grinding capabilities can break down solid materials before they reach the impeller, minimizing clogging risk. Another effective solution is using a submersible agitator pump, which keeps solids suspended in the fluid, reducing sediment buildup. Regular cleaning of intake screens prevents debris accumulation in your sewage system. Inspecting discharge lines for blockages allows early detection and correction. Installing a drain cleanout provides access for clearing clogs. Educating users about what should not enter the system prevents many common clogging issues.

Float Switch Malfunction

A malfunctioning float switch is one of the most common problems encountered with submersible sump pumps and sewage systems. The float switch is responsible for activating the sewage pump when the water reaches a certain level. If it fails, the pump may either not turn on when needed or continue running even after water has been removed.

Symptoms of float switch malfunction include the pump failing to turn on when water levels rise in the sump or tank. The pump running continuously even after water has been removed from the system. Float switch arm appearing stuck or unable to move freely in its housing. Water accumulated in the switch housing indicating seal failure. Intermittent operation where the pump activates and stops unexpectedly. No response when manually testing the float switch mechanism.

Solutions to troubleshoot float switch problems include checking for obstructions around the float switch that could impede movement. Cleaning debris from around the switch mechanism allows proper function restoration. If the switch is damaged or corroded, consider replacing it with a new one designed for your specific pump model. Some modern submersible drainage pumps and submersible dewatering pumps come equipped with more reliable electronic switches less prone to mechanical failure. Testing the switch manually by moving it through its full range identifies binding points. Replacing the entire switch assembly resolves most float switch issues permanently.

Motor Failures in Sewage Pumps

The motor is the heart of any submersible pump, and motor failure can be a significant issue affecting your entire sewage system. Motors in single phase submersible pumps and submersible pumps 1 hp or submersible pumps 1.5 hp are designed to handle tough conditions but can still succumb to overheating, water intrusion, or electrical issues.

Common causes of motor failures in sewage pumps include water intrusion into the motor housing due to seal failure or cracks. Overheating from continuous operation without adequate cooling or submersion depth. Electrical surges or voltage fluctuations damaging motor windings. Corrosion of motor components from prolonged exposure to harsh sewage environments. Bearing wear from extended operation without proper lubrication. Mechanical jamming of the motor rotor from debris or sediment accumulation. Manufacturing defects in motor windings or electrical components affecting performance.

Solutions for motor failure include routine inspections of the motor housing to identify signs of wear, corrosion, or water intrusion before failure occurs. Ensure your sewage pump motor has adequate cooling, especially in submersible water pumps used for continuous operation. Maintaining proper submersion depth ensures the motor receives cooling from the surrounding fluid. Installing voltage protection devices prevents electrical damage to the motor. Regular testing of motor performance and listening for abnormal sounds identifies developing problems early. If your motor is damaged beyond repair, replacing it with the best submersible pump designed for your application, such as a submersible sewage pump, restores system functionality.

Overheating and Pump Burnout

Overheating is a common issue in submersible pumps, particularly in submersible dewatering pumps or slurry pumps that operate under heavy loads for extended periods. Overheating can cause significant damage to the pump's motor and internal components, eventually leading to total pump failure and system shutdown.

Symptoms of overheating in your sewage pump include hot discharge water indicating excessive internal friction and heat generation. Unusual burning smell coming from the pump motor area. Automatic shutoff of the pump likely due to thermal protection activation. Reduced pumping capacity despite proper operation previously. Visible steam or vapor coming from the pump. Circuit breaker tripping frequently suggesting excessive current draw from overheating motor. Pump motor exterior becoming too hot to touch safely.

Solutions to prevent overheating include ensuring the pump is adequately submerged at all times to allow for proper cooling from the surrounding fluid. Installing a submersible drainage pump designed for continuous operation in demanding environments reduces overheating likelihood. Using a dewatering pump 1 hp or a submersible slurry pump with enhanced cooling features benefits extended use. Reducing operational duty cycle by installing larger capacity tanks decreases run time. Adding external cooling fans to pump installations in hot environments improves heat dissipation. Regular cleaning of cooling surfaces and intake areas maintains heat transfer efficiency. Monitoring discharge temperature detects overheating early for corrective action.

Leaking and Water Intrusion Issues

Leaks in a submersible pump occur when seals around the motor housing wear out or break down. When water seeps into the motor, it causes electrical shorts, motor failure, and complete pump burnout. This is particularly concerning for sewage sludge pumps, where leaks lead to environmental contamination and system failure.

Symptoms of leaking or water intrusion include visible water dripping from the pump motor housing or connections. Electricity or sparking sounds indicating electrical short circuits in the motor. Pump failing to start or shutting off immediately after starting. Visible corrosion or rust on normally dry motor surfaces indicating internal moisture. Loss of power or reduced motor performance suggesting water damage to electrical components. Unusual electrical smell coming from the pump area. Water visible in the motor cable at connection points.

Solutions for leaking or water intrusion include inspecting and replacing worn seals on the motor housing and cable entries immediately. Regular inspection and maintenance of seals, particularly in submersible dewatering pumps and sewage pumps, prevents water intrusion and prolongs pump life. Checking cable entry seals for cracks or deterioration prevents water entry at connection points. Replacing the entire cable assembly if water has entered the motor housing. Installing a new pump if internal motor components have suffered water damage and corrosion. Ensuring proper strain relief on cables prevents pulling on seals. Adding cable protectors and conduit provides additional protection.

Impeller Damage in Sewage Pumps

Impellers are critical components that move water and waste through the sewage system. They are particularly important in submersible sewage pumps and cutter pump sewage applications. Over time, the impeller may become damaged due to debris, corrosion, or wear, drastically reducing the pump's efficiency and performance.

Symptoms of impeller damage include significant reduction in water flow and discharge from the system. Unusual vibration or rattling sounds during pump operation indicating impeller imbalance. Visible cracks, chips, or missing pieces on the impeller blade. Decreased pumping efficiency despite normal motor operation and speed. Grinding sounds during operation suggesting impeller striking the pump housing. Loss of pressure in the discharge line indicating leakage around damaged impeller. Water leaking from the pump casing around the impeller area.

Solutions for impeller damage include inspecting the impeller for damage such as cracks, chips, or debris buildup reducing efficiency. If damage is detected, the impeller may need replacement with a new one designed for your specific pump model. Choosing high-quality slurry pumps or submersible agitator pumps from reputable slurry pump manufacturers improves impeller durability. Removing debris from the pump and system prevents future impeller damage. Replacing the entire pump if internal corrosion or damage is extensive. Installing wear-resistant impellers in systems handling abrasive materials. Regular inspection catches impeller wear before complete failure.

Maintenance Tips for Dewatering Pumps

Dewatering pumps for construction projects are designed to remove groundwater and prevent flooding on job sites. These pumps undergo heavy-duty use, making regular maintenance crucial for reliability. Whether using a submersible dewatering pump or a dewatering pump submersible, maintaining optimal condition saves time and money.

Tips for maintaining dewatering pumps include inspecting intake screens daily and cleaning them to prevent clogging from construction debris. Testing the pump daily before starting dewatering operations ensures proper function. Draining the pump housing and discharge lines at the end of each day prevents sediment accumulation. Checking all connections and hoses for leaks or damage before each use. Storing the pump in a protected location away from harsh weather when not in use. Performing comprehensive maintenance checks weekly during extended project use. Keeping the pump fully submerged during operation ensures proper cooling. Documenting all maintenance activities for warranty and service records. Using dewatering pumps from reputable dewatering pump manufacturers ensures access to parts and service when needed, reducing project downtime.

Selecting the Best Submersible Pump for Your Needs

Choosing the right pump for your specific application is crucial for reliable sewage system performance. For general sewage handling, a submersible sewage pump or slurry pump typically suffices. However, for applications requiring handling of solids and fibrous materials, a cutter pump or cutter pump sewage system with grinding capabilities prevents clogs.

Factors to consider when selecting a submersible pump include evaluating your specific application requirements and waste type. Calculating the required flow rate and head pressure for your system. Determining power requirements based on available electrical service. Assessing solid handling needs for your particular waste stream. Considering installation space and environmental conditions. Reviewing maintenance requirements and parts availability. Checking pump warranty and manufacturer support options. For industrial and heavy-duty applications, dewatering pumps for construction and slurry pumps designed for tough environments provide appropriate solutions.

Conclusion: Preventing Sewage Pump Failure Through Proper Troubleshooting

Troubleshooting submersible pumps, including submersible sewage pumps, dewatering pumps, and slurry pumps, is essential for preventing downtime and costly repairs. By recognizing common problems like clogging, float switch malfunctions, motor failures, overheating, leaks, and impeller damage, you can extend your pump's life and ensure efficient operation.

Whether you need a submersible pump 1 hp for residential use or a dewatering pump 1 hp for a construction site, understanding common issues and maintenance requirements is critical. Additionally, selecting high-quality pumps from reliable dewatering pump manufacturers and slurry pump manufacturers ensures you have the best tools to keep your sewage system running smoothly for years to come. Regular maintenance, early problem identification, and timely repairs ensure your sewage pump operates efficiently throughout its operational life.