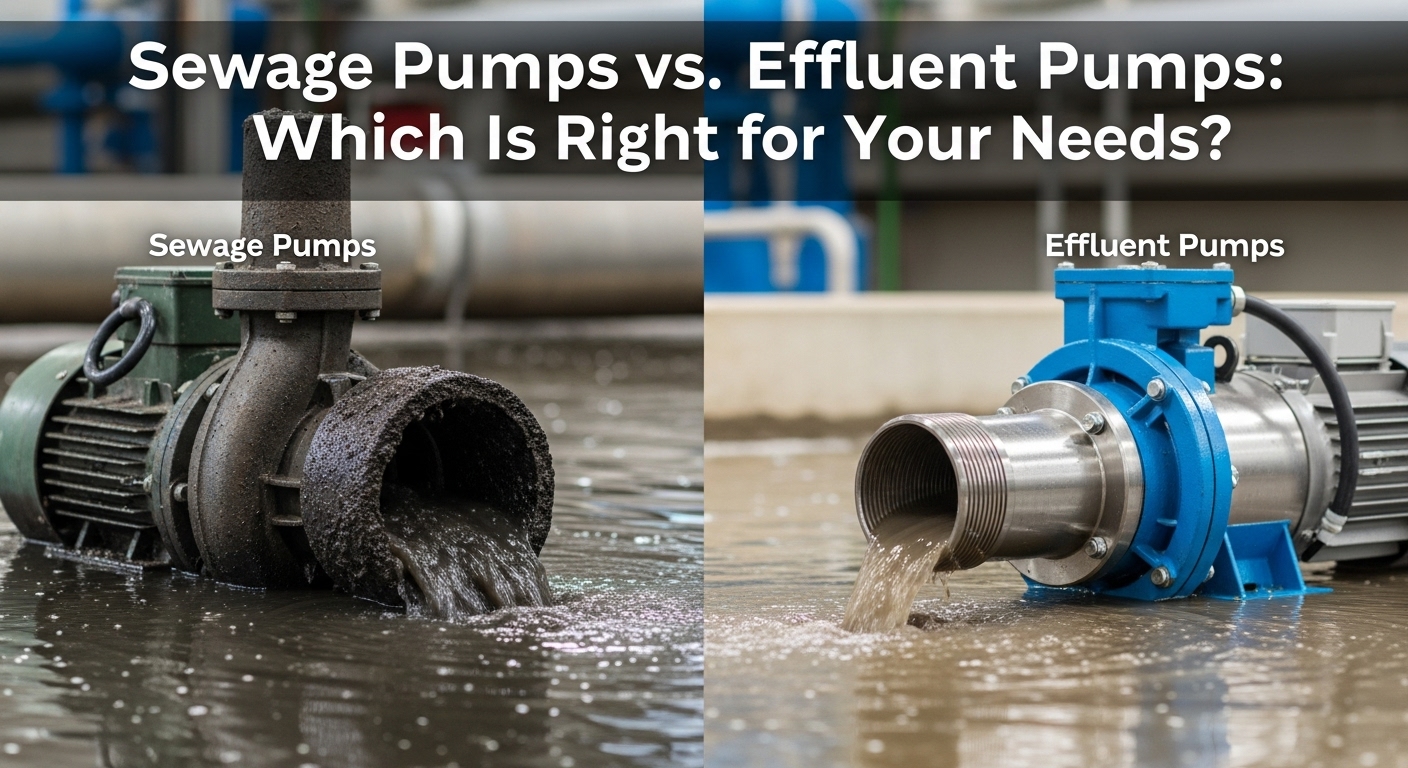

Sewage Pumps vs. Effluent Pumps: Choosing the Right Solution for Wastewater Management

Wastewater management is a critical aspect of any home, business, or industrial operation requiring proper handling and treatment. Whether you're dealing with raw sewage, excess water, or gray water from a septic system, the right pump can make all the difference in keeping your system functioning smoothly and reliably. In this comprehensive guide, we explore the differences between sewage pumps and effluent pumps and guide you through choosing the right solution based on your specific needs. Along the way, we also discuss other important pump types, such as submersible pumps, slurry pumps, and dewatering pumps, providing insights into key features like cutter pumps and submersible sump pumps.

What Is a Sewage Pump and How It Works

A sewage pump is specifically designed to transport raw sewage, which includes both liquids and substantial solid waste materials. These essential pumps are most commonly used in residential, commercial, and industrial settings where waste must be moved from a lower level, such as a basement, to a higher level like a septic tank or municipal sewage treatment plant. A submersible sewage pump is often used for these critical tasks, as it can be placed directly in the waste-filled sump pit without external installation complications.

Key features of reliable sewage pumps include their robust construction designed to handle raw, unfiltered sewage containing various debris. Sewage pumps typically feature powerful motors capable of grinding solids and preventing clogs in your system. These pumps include check valves that prevent backflow of untreated sewage into your facility. Sewage pumps come equipped with automatic float switches that activate the pump when waste levels rise. The submersible design keeps sewage pumps sealed to protect the motor from contamination. Durable impellers in sewage pumps resist corrosion from harsh wastewater environments. Most sewage pumps operate continuously to manage high volumes of raw waste.

For homeowners, a submersible sewage pump is often installed in basements where bathrooms are located below the sewer line. This critical pump ensures waste is efficiently moved out of the building, preventing dangerous backups and potential water damage to property. Commercial applications, such as hotels, restaurants, and public buildings, often use cutter pump sewage systems, which include sharp blades designed to grind larger solids into manageable sizes for treatment.

What Is an Effluent Pump and Its Applications

An effluent pump is specifically designed to handle the partially treated wastewater that exits from a septic tank after initial treatment processes. This specialized pump moves water that contains smaller solids, usually up to three-quarters of an inch in diameter, from the septic system to a drain field or secondary treatment area for final processing. Unlike sewage pumps designed for raw waste, effluent pumps are not engineered to handle raw sewage or large solid materials.

Effluent pumps are ideal for managing wastewater in systems with septic tanks requiring distribution to drain fields. These pumps work effectively in residential and small commercial properties using septic systems for wastewater treatment. Effluent pumps excel at moving treated water that has been pre-processed by the septic tank. These pumps maintain efficient operation in systems requiring water pressure to reach higher drain field locations. Effluent pumps are perfect for properties where gravity alone cannot move treated wastewater to the final dispersal area. The submersible water pump is often used in effluent systems, especially in residential applications, as these pumps are reliable and can be installed directly in the septic tank for continuous operation.

Key Differences Between Sewage and Effluent Pumps

Understanding the primary differences between sewage pumps and effluent pumps helps you determine which one is right for your specific wastewater management needs. These distinctions are critical for system efficiency and longevity.

Applications differ significantly between these pump types. Sewage pumps handle raw, untreated wastewater containing all solids and debris from residential and commercial facilities. Effluent pumps manage pre-treated water from septic tanks with significantly smaller particles. The distinction in applications ensures each pump type performs optimally for its intended purpose.

Solids handling capabilities vary considerably between sewage and effluent pumps. Sewage pumps are engineered to process raw solids of various sizes without clogging or damage. Effluent pumps handle only small solids up to three-quarters inch, as larger particles have been removed during septic tank treatment. This difference reflects the distinct processing stages of wastewater treatment systems.

Power and size requirements differ based on application demands. Sewage pumps typically feature more powerful motors to handle the greater viscosity and solid content of raw sewage. Effluent pumps often use smaller, less powerful motors since treated water flows more easily. The size and horsepower differences affect installation space requirements and energy consumption for your system.

Understanding Submersible Pumps and Their Versatility

A submersible pump is a versatile and reliable pump that can be used in various applications, including sewage management, effluent handling, and water dewatering. These pumps are sealed units that operate completely underwater, making them ideal for wet environments and submerged applications requiring robust performance.

There are many types of submersible pumps available to choose from depending on your specific requirements. Submersible sewage pumps handle raw wastewater in residential and commercial settings. Effluent submersible pumps manage treated water from septic systems efficiently. Submersible sump pumps remove unwanted water from basements and crawl spaces preventing flooding. Dewatering submersible pumps remove excess water from construction sites and other temporary water accumulation areas. Slurry submersible pumps handle thick, abrasive materials in mining and industrial applications. Single phase submersible pumps provide residential-grade power for home wastewater systems.

For construction and dewatering needs, the submersible dewatering pump is essential and highly reliable. Whether you're managing water accumulation in construction trenches, excavations, or need to keep a basement dry and protected, the dewatering pump handles the task effectively. It's available in different power ranges like the dewatering pump 1 hp, which provides the necessary strength and reliability for medium-sized water removal tasks.

The Role of Cutter Pumps and Slurry Pumps in Wastewater Management

In commercial and industrial applications, a cutter pump is often used to deal with waste containing larger solids or fibrous materials that could clog traditional sewage pumps. A cutter pump sewage system includes sharp rotating blades that effectively shred solid waste into smaller, more manageable pieces. This design makes cutter pumps ideal for challenging environments like hotels, restaurants, and public restrooms where foreign objects frequently enter the waste stream.

On the other hand, a slurry pump is engineered to handle thick, abrasive liquids containing substantial solid particles requiring specialized handling. Slurry pump manufacturers design these robust pumps for demanding industries such as mining, construction, and manufacturing, where heavy-duty pumping of difficult materials is required continuously. A submersible slurry pump can operate directly in the material it's pumping, reducing the risk of damage from abrasion and extending equipment lifespan significantly.

Choosing the Right Pump for Your Specific Needs

Selecting the right pump depends on understanding the type of waste you need to manage and the specific application requirements. For residential sewage systems, a submersible sewage pump is typically the best choice for handling raw wastewater efficiently. If you operate a septic tank system, an effluent pump is more appropriate for moving treated wastewater to drain fields. For construction and temporary dewatering, a submersible dewatering pump removes water from excavations quickly. In industrial settings handling slurry or thick, abrasive materials, a submersible slurry pump provides the robust performance needed. For commercial facilities with high solid content in waste, a cutter pump sewage system prevents clogs and maintains continuous operation. For residential basement water removal, a submersible sump pump provides reliable protection against flooding and water damage.

Single-Phase Submersible Pumps for Residential Applications

For residential use, a single phase submersible pump is often the most practical and cost-effective choice available. These pumps are easier to install and operate than three-phase industrial pumps, making them ideal for homeowners who need a reliable solution for managing water or wastewater. Single phase pumps connect to standard household electrical systems without requiring specialized electrical infrastructure.

In homes with basements, a submersible sump pump is crucial for removing unwanted water accumulation and preventing flooding. This essential sump pump can help prevent costly water damage by pumping water away from the foundation and into a designated drainage area away from the structure. Single phase submersible pumps provide reliable residential wastewater management for properties using septic systems or other decentralized treatment solutions.

Maintenance Tips for Sewage and Effluent Pumps

To ensure the longevity and efficiency of your sewage pump or effluent pump, regular maintenance is absolutely key to system reliability. Performing regular inspections of your sewage pump helps identify signs of wear, damage, or potential problems before they become serious issues. Checking for visible leaks, unusual noises, or vibrations allows early detection of developing problems. Replacing any worn-out parts immediately prevents complete pump failure and system backups.

Cleaning your pump regularly is essential for maintaining efficiency and preventing clogs from solids. For sewage pumps specifically, regularly cleaning the pump and impeller prevents accumulation of debris that can cause blockages. Flushing suction and discharge lines removes sediment buildup affecting pump performance. If you rely on a battery backup system for your pump, testing it periodically ensures it functions properly during power outages. Regular testing of float switches confirms automatic operation works correctly. Checking electrical connections verifies the pump receives proper power. Inspecting cable integrity prevents electrical hazards and ensures reliable operation of your sewage pump system.

Dewatering and Drainage in Construction Applications

Construction sites often require specialized pumps to manage excess water that accumulates during building projects and excavation work. Dewatering pumps for construction are specifically designed to remove this water efficiently, ensuring that construction work can proceed without delays or complications. Submersible drainage pumps are commonly used in construction to handle rainwater, groundwater, or other unwanted liquid accumulations that occur during active projects.

For contractors and construction managers, finding the best submersible pump is crucial for keeping projects on schedule and within budget. Whether you need a submersible drainage pump for temporary water removal or a dewatering pump submersible for ongoing site management, many manufacturers provide a wide range of options tailored to the specific needs of the construction industry. These specialized pumps ensure construction sites remain dry and safe for worker productivity.

Conclusion: Making the Right Pump Choice for Your Wastewater System

Choosing the right pump for your wastewater management needs depends on the type of waste you handle, the specific application requirements, and the environment in which the pump will operate. From sewage pumps for raw wastewater to effluent pumps for treated water, and from slurry pumps for industrial applications to dewatering pumps for construction, understanding the key differences between these systems helps you make an informed decision.

Whether you're looking for a submersible pump for residential use or need industrial-grade solutions like a submersible agitator pump or slurry pump for demanding applications, the right choice will ensure efficient and reliable performance for years to come. For high-demand applications and specialized requirements, consulting with reputable sludge pump manufacturers and dewatering pump manufacturers can help you find robust, dependable options that can handle your toughest challenges and provide long-term value.