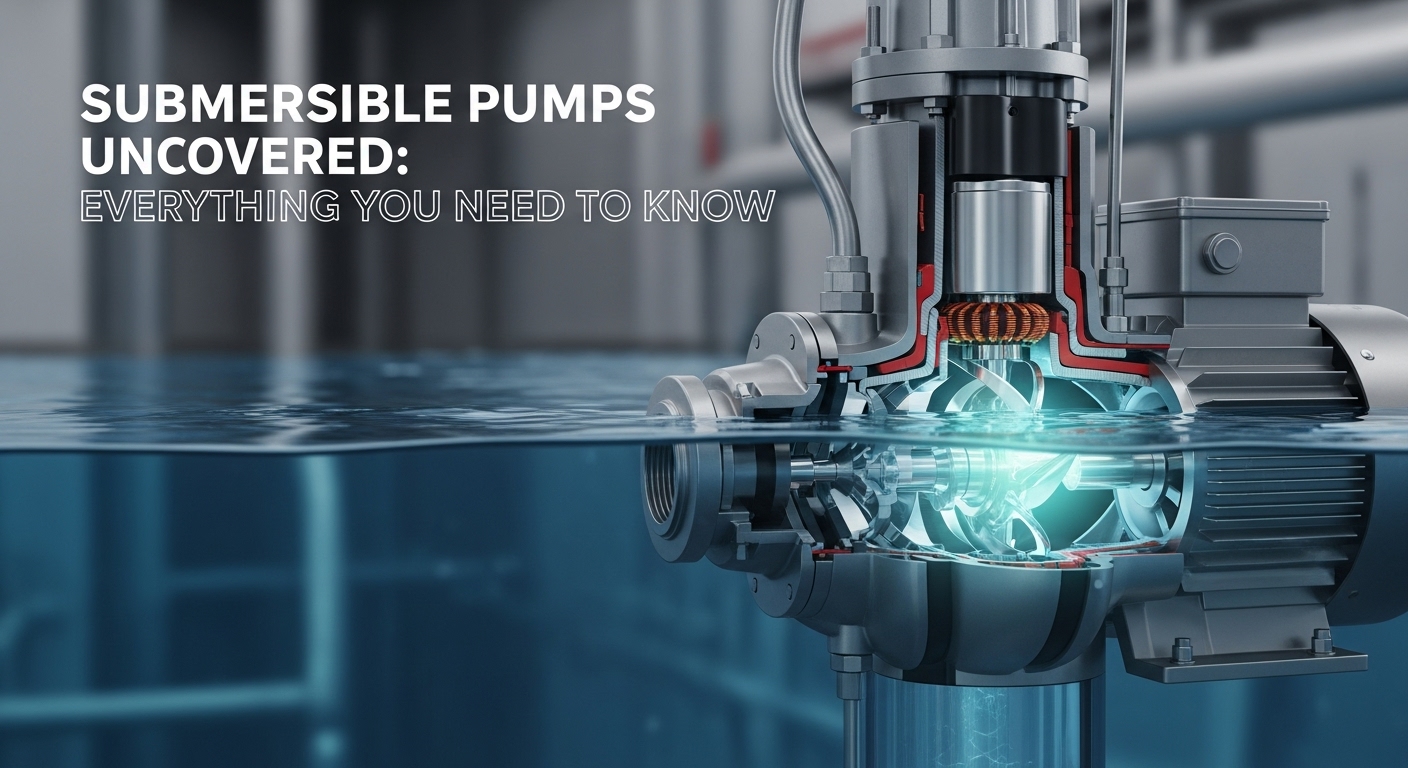

Submersible pumps, engineered to operate while submerged in liquid, are a cornerstone of efficient fluid handling in numerous environments. The design and engineering of these pumps not only ensure their functionality but also enhance their durability and adaptability to various applications, from deep wells to municipal wastewater systems.

Materials and Construction

The construction of a submersible pump is pivotal in determining its suitability for specific tasks. Material selection is critical due to the diverse environments in which these pumps operate. High-quality submersible pumps are constructed using corrosion-resistant materials such as stainless steel, cast iron, and specialized alloys. These materials ensure longevity and reliability even when exposed to harsh, abrasive, or chemically challenging fluids. The pump housing must be robust enough to withstand the pressure of deep submersion while maintaining structural integrity over extended operational periods.

Sealing Systems

Seals are crucial to protect the motor of a submersible pump from fluid ingress. Advanced seal designs, such as mechanical seals and elastomer components, prevent water and debris from entering the motor chamber. These sealing systems are engineered to maintain their integrity under varying pressure conditions and prolonged submersion. Proper sealing ensures that the pump's electrical components remain dry and functional, extending the pump's operational lifespan and preventing premature motor failure.

Impeller Design

The impeller is the heart of the submersible pump's hydraulic design. Different impeller configurations are engineered for specific applications—centrifugal impellers for general fluid movement, multi-stage impellers for higher pressure requirements, and specialized designs for handling solids-laden fluids. The impeller's shape, blade angle, and material composition directly influence the pump's efficiency, flow rate, and ability to handle various fluid types. Modern impellers are designed to minimize cavitation and turbulence, improving overall system performance.

Motor Engineering

Submersible pump motors must be compact and efficient while capable of operating in submerged conditions without overheating. These motors are typically three-phase or single-phase electrical motors enclosed within the pump housing. Thermal protection systems prevent overheating, while advanced cooling mechanisms, often utilizing the pumped fluid itself, maintain optimal operating temperatures. Motor design also incorporates features such as voltage regulation and surge protection to ensure reliable operation under variable electrical conditions.

Innovative Technologies

Advancements in submersible pump engineering continue to push the boundaries of their capabilities. Variable frequency drives (VFDs) allow for speed adjustment, improving energy efficiency and reducing operational costs. IoT integration enables remote monitoring and predictive maintenance, alerting users to potential issues before they cause system failures. Smart sensors measure flow rates, pressure, and temperature in real-time, optimizing pump performance and extending service life. These innovations represent the future of fluid handling technology.

Agriculture and Irrigation

In agriculture, submersible pumps are vital for irrigation and draining fields. They provide a consistent water supply, essential for crop growth, and are particularly effective in drought-prone areas. Submersible irrigation pumps, designed to operate efficiently over long periods, reduce water wastage and energy consumption. Farmers rely on these pumps to access groundwater resources and maintain optimal soil moisture levels for maximum crop yields.

Mining and Construction

Submersible dewatering pumps are crucial in mining and construction. These industries often encounter groundwater or surface water that must be removed to maintain a safe working environment and protect equipment. The pumps used here are robust, designed to handle abrasive particles, and often feature high levels of solid handling capabilities. Dewatering operations ensure that excavation sites remain dry and accessible, enabling efficient resource extraction and construction progress.

Municipal and Wastewater Management

Cities rely on submersible sewage pumps to transport wastewater from residential and commercial areas to treatment facilities. These pumps handle large volumes of water mixed with solid waste, operating continuously to prevent sewage backups. Innovations like cutter pumps have been developed to handle large waste materials, reducing clogging and maintenance costs. Municipal systems depend on the reliability and durability of these pumps to maintain public health and environmental protection.

Environmental Management

In environmental applications, submersible pumps help manage and treat polluted waters, such as in ponds, lakes, and remediation projects. Submersible sludge pumps are used to handle sludges and sediments, vital in cleaning and restoring aquatic environments. These pumps enable the removal of contaminated materials and facilitate environmental remediation efforts, contributing to ecosystem restoration and water quality improvement.

Industrial Applications

In heavy industries, submersible pumps handle harsh fluids, including chemicals, heated effluents, and oil. Submersible chemical pumps, often made from materials resistant to corrosive liquids, are essential for maintaining the flow of materials in chemical processing plants. Industrial applications demand pumps with exceptional durability and resistance to extreme conditions, making quality engineering a critical investment.

Innovative Uses

Submersible pumps are also found in innovative applications, such as geothermal systems for energy production, where they circulate fluid through the earth's crust to extract heat. These emerging applications demonstrate the adaptability of submersible pump technology and its critical role in energy sustainability. As renewable energy technologies advance, submersible pumps continue to enable new possibilities for clean and sustainable power generation.

Conclusion

The design and engineering of submersible pumps focus on maximizing efficiency, extending lifespan, and reducing maintenance needs. This careful balance of component choice, mechanical design, and innovative technology ensures that these pumps can meet the increasing demands of modern applications across various industries. From agricultural irrigation to municipal wastewater management and cutting-edge renewable energy systems, submersible pumps remain indispensable tools in fluid handling and management.