Water pumps are essential for ensuring a reliable water supply across residential, agricultural, and industrial applications. Two of the most commonly used pump types are the submersible pump and the jet pump. Each pump operates on a different principle, and choosing the right option depends on factors such as well depth, water demand, efficiency, maintenance, and long-term operating costs. This detailed comparison will help you determine the best solution for your specific requirements.

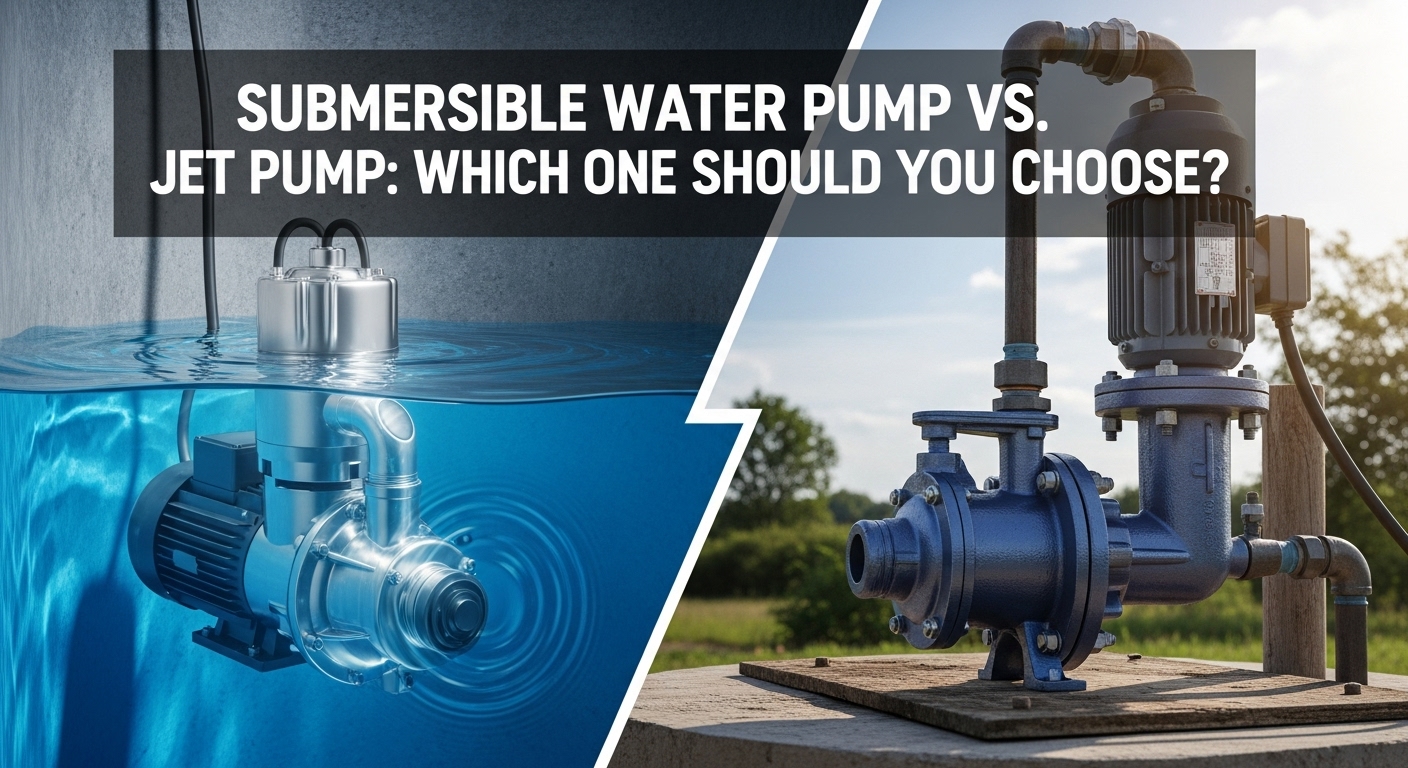

Submersible Pump vs Jet Pump: Which Water Pump Is Better?

Key Takeaways

What Is a Submersible Pump?

A submersible pump is designed to operate completely underwater, pushing water to the surface rather than pulling it. This design makes it highly efficient and quiet, particularly for deep wells, borewells, irrigation systems, industrial processes, and dewatering pump applications.

How Does a Submersible Pump Work?

The pump is placed below the water level, where an electric motor drives the impeller to push water upward through the discharge pipe. Because it works with water pressure instead of suction, energy losses are minimal.

Advantages of Submersible Pumps

Disadvantages of Submersible Pumps

What Is a Jet Pump?

A jet pump is an above-ground pump that uses suction and pressure to draw water from a source. It is commonly used in residential and small-scale applications where the water table is relatively shallow.

Types of Jet Pumps

- Shallow well jet pump – suitable for depths up to 25 feet

- Deep well jet pump – capable of drawing water from depths up to 100 feet

Advantages of Jet Pumps

Disadvantages of Jet Pumps

Submersible Water Pump vs Jet Pump: Key Comparisons

Understanding the differences between a submersible water pump and a jet pump is essential for making the right decision.

Factors to Consider When Choosing a Pump

1. Depth of the Well

Deep wells typically require submersible pumps, while shallow wells can function efficiently with jet pumps.

2. Water Demand

High water demand for irrigation or industrial use favors submersible pump systems.

3. Energy Efficiency

Submersible pumps consume less energy over time, reducing operating costs.

4. Maintenance and Accessibility

Jet pumps are easier to access, but submersible pumps offer greater durability.

Installation and Maintenance

Submersible Pump Installation

- Lowered into the water source with proper sealing.

- Connected using waterproof electrical components.

Jet Pump Installation

- Mounted above ground near the water source.

- Requires proper priming to avoid airlocks.

Common Maintenance Issues

Submersible pumps may experience seal wear or cable damage, while jet pumps commonly face priming and suction-related issues.

Environmental and Energy Considerations

Submersible pumps are generally more environmentally friendly due to lower power consumption and higher efficiency, especially in long-term use.

Use Cases for Submersible and Jet Pumps

When to Use a Submersible Pump

Ideal for deep wells, high water demand, irrigation systems, wastewater handling, and continuous-duty industrial applications.

When to Use a Jet Pump

Best suited for shallow wells, residential water supply, and situations where easy maintenance access is required.

Conclusion

Choosing between a submersible water pump and a jet pump depends on your application, well depth, and efficiency requirements. For deep wells, quiet operation, and long-term energy savings, the best submersible pump is the superior choice. For shallow wells and budget-conscious installations, jet pumps remain a practical option. By carefully assessing water demand, operating conditions, and lifecycle costs, you can select a pump solution that delivers reliable performance and long-term value.