Urban construction projects are complex operations that face constant challenges related to space constraints, soil conditions, groundwater intrusion, and unpredictable weather. One of the most critical challenges is managing excess water at construction sites, including groundwater seepage, rainwater accumulation, and surface runoff. This is where a dewatering pump becomes essential. Dewatering refers to the process of removing water from soil or solid material through pumping, filtration, centrifugation, or other solid–liquid separation methods to create stable and workable site conditions.

The Role of Dewatering Pumps in Urban Construction Projects

Effective dewatering allows construction activities to proceed safely and on schedule while preventing water-related issues that can compromise foundation stability and underground structures. From excavation pits to basements and tunnels, proper dewatering is a fundamental requirement in modern urban construction. This guide explores why dewatering is critical, the types of dewatering pumps used, common dewatering methods, and best practices for reliable water management on construction sites.

Why Dewatering Is Critical in Urban Construction

Excess water at construction sites can severely affect soil strength and load-bearing capacity, leading to unstable excavation walls and foundation failures. Water infiltration can weaken concrete, corrode reinforcement, and cause long-term structural damage if not addressed properly.

Beyond structural concerns, standing water can halt construction work entirely, delay timelines, and significantly increase project costs. Slippery surfaces also raise safety risks for workers. By using the right dewatering pump solution, construction teams maintain dry working conditions, improve site safety, and ensure consistent project progress.

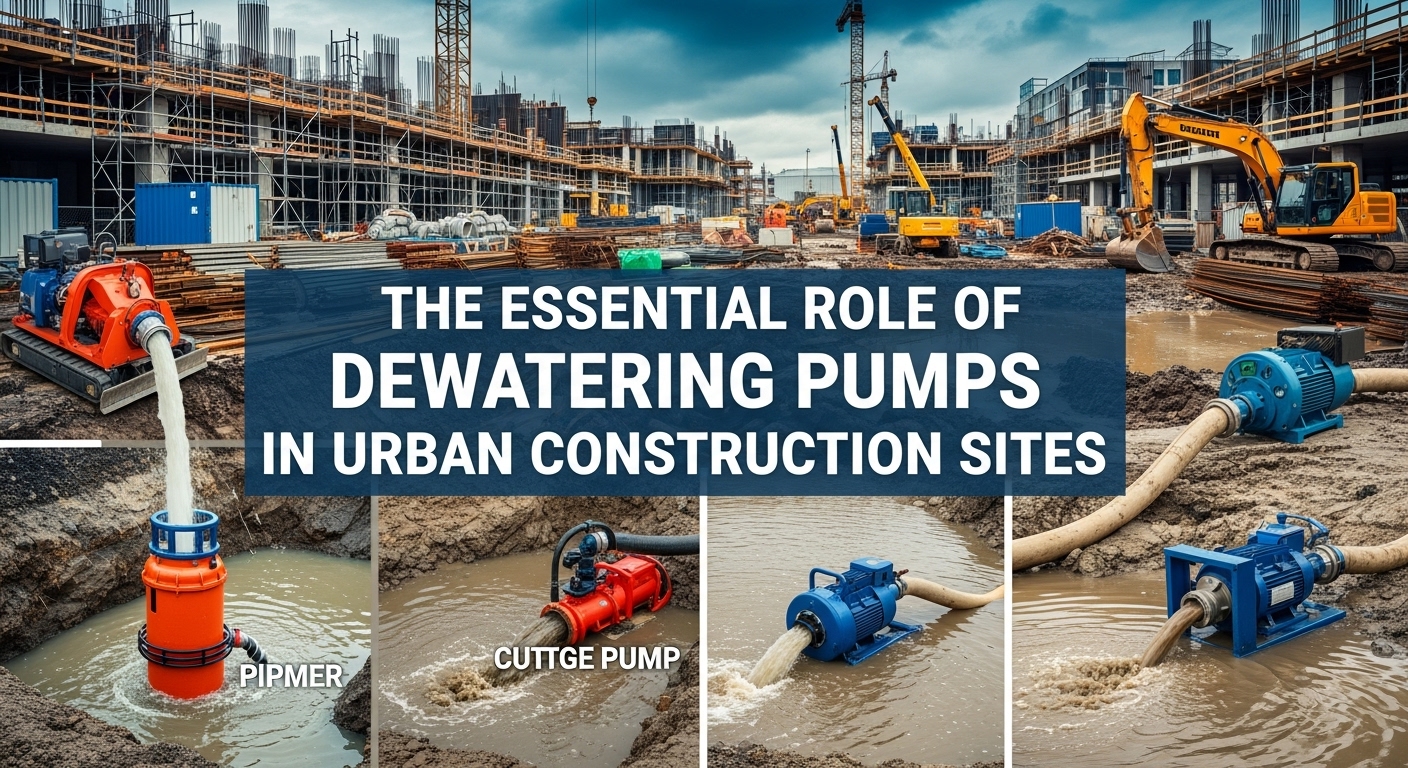

Types of Dewatering Pumps Used in Construction

Submersible Pump

Submersible pumps are designed to operate fully submerged in water, making them ideal for deep excavations and high groundwater conditions. Their sealed construction prevents water ingress into the motor, enabling continuous operation in harsh environments. A commonly used option in construction is the submersible dewatering pump, which is built to handle heavy water flow and abrasive site conditions commonly found in urban projects.

Centrifugal Pump

Centrifugal pumps move water using a rotating impeller that converts mechanical energy into hydraulic energy. These pumps are suitable for shallow water removal and surface water drainage. Their simple design, ease of maintenance, and ability to handle large volumes make them a popular choice for general construction dewatering tasks.

Diaphragm Pumps and Cutter Pump

Diaphragm pumps are effective for muddy water containing sand, silt, or debris. They use a flexible diaphragm to create suction and discharge, making them reliable in challenging site conditions. A cutter pump, on the other hand, is equipped with cutting blades that shred fibrous solids and waste, making it ideal for sewage-laden water commonly encountered during excavation and rehabilitation projects.

Sludge Pump and Sewage Sludge Pump

Sludge pumps and sewage sludge pumps are designed to handle thick, viscous mixtures of water, soil, and solid waste. These pumps are essential for large-scale excavation projects where contaminated or sediment-heavy water must be removed efficiently.

From managing groundwater with a submersible pump 1 HP to handling waste using a submersible sewage pump, selecting the correct pump type is critical to effective site dewatering.

Dewatering Methods in Urban Construction

Choosing the right dewatering method depends on soil type, excavation depth, groundwater level, and project duration. Common dewatering techniques used in urban construction include:

Open Sump Pumping

Open sump pumping involves excavating pits at low points around the site where water naturally collects. Dewatering pumps remove water from these sumps, making this method simple and cost-effective for shallow excavations and surface water control.

Wellpoint Systems

Wellpoint systems use a series of closely spaced small wells connected to a header pipe and vacuum pump. This setup lowers the groundwater table around the excavation and is ideal for shallow to medium-depth projects in permeable soils.

Ejector Systems

Ejector systems are used for deeper excavations and low-permeability soils. They use high-pressure water to create a vacuum that lifts groundwater. These systems are effective where traditional wellpoints are insufficient.

Deepwell Systems

Deepwell systems involve drilling boreholes fitted with submersible dewatering pumps. These systems handle large volumes of water and are ideal for deep basements, tunnels, and major urban infrastructure projects.

Best Practices for Dewatering in Construction

Successful dewatering requires more than pump selection. It demands careful planning, monitoring, and responsible water management.

Regular Maintenance

Dewatering equipment such as the drainage pump and submersible sewage pump must be inspected regularly to prevent breakdowns. Cleaning intakes, checking seals, and monitoring motor performance ensure uninterrupted operation.

Continuous Monitoring

Monitoring groundwater levels, pump performance, and excavation stability allows teams to respond quickly to changing site conditions. Early detection of issues prevents delays, equipment damage, and safety risks.

Water Treatment and Environmental Compliance

If pumped water contains sediments or contaminants, it must be treated before discharge. Sedimentation tanks, filtration systems, or chemical treatment may be required to meet environmental regulations and prevent pollution.

Conclusion: Dewatering Pumps as a Foundation of Urban Construction

Dewatering is a cornerstone of successful urban construction. The strategic use of dewatering solutions such as submersible pump 1 HP, drainage pump, sludge pump, sewage sludge pump, submersible sewage pump, and cutter pump significantly reduces risks associated with groundwater and surface water at construction sites.

By selecting the appropriate dewatering method and pump type, construction teams can maintain dry, stable working conditions, improve safety, and protect structural integrity. As urban construction continues to grow in scale and complexity, efficient dewatering is no longer optional—it is a critical component of modern construction practices that ensures projects are completed safely, on time, and in compliance with environmental standards.