The Importance of Proper Ventilation in Sewage Pump Systems

Proper ventilation in sewage pump systems is critical for maintaining operational efficiency, safety, and longevity. Sewage pump systems are a vital component in managing waste, particularly in areas where gravity-fed systems are not feasible. This blog will explore the significance of ventilation and dive into various types of pumps, from submersible pumps to slurry pumps, and their specific uses in sewage and dewatering applications. Throughout, we’ll discuss different pump types and their applications in various settings, including residential, industrial, and commercial.

Understanding Sewage Pump Systems

Sewage pump systems are used to move wastewater and sewage from low-lying areas to higher ground, typically to a treatment facility or a septic system. Without proper ventilation, these systems could malfunction, leading to environmental hazards, foul odors, and operational inefficiencies.

Sewage pump systems typically consist of components like submersible sewage pumps, vent pipes, float switches, and check valves. A crucial part of ensuring these components work in harmony is maintaining proper air pressure and gas flow through adequate ventilation. When a pump expels water, pressure builds within the system, and without a vent to release trapped air, the pump may become airlocked, which hinders its ability to move wastewater effectively.

Ventilation also plays a key role in managing gases produced by sewage, including methane and hydrogen sulfide, which are not only malodorous but potentially dangerous. Ensuring these gases are safely vented from the system prevents them from accumulating in the pump basin or nearby areas.

The Role of Submersible Pumps in Sewage Systems

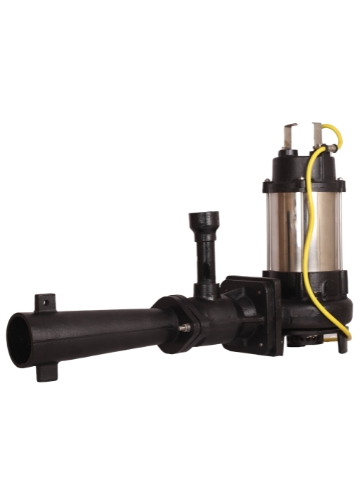

One of the most common types of pumps used in sewage systems is the submersible pump. These pumps are designed to operate underwater, making them ideal for moving large volumes of wastewater or slurry. submersible pumps are housed in waterproof casings that protect their motors from water damage, allowing them to function efficiently in submerged environments. Proper ventilation helps these pumps by allowing trapped gases to escape, thus preventing airlocks and pressure build-up.

There are various types of submersible pumps, each designed for specific applications:

- Submersible pump 1 hp: Ideal for residential sewage or small-scale dewatering tasks.

- Submersible pump 1.5 hp: A more powerful option suitable for larger residential systems or light industrial applications.

- Submersible water pump: These are typically used for clean water applications, such as draining flooded areas or irrigation.

- Submersible sewage pump: Specifically designed for handling solid waste and wastewater.

Ventilation and Different Pump Applications

Proper ventilation is essential in different types of sewage systems, whether they are handling liquid waste, slurry, or sludge. Below, we’ll look at how ventilation affects various pump types and their unique uses.

Dewatering Pumps

Dewatering is the process of removing water from a location, typically during construction or after flooding. A dewatering pump is critical for ensuring water doesn’t accumulate in construction sites, basements, or other low-lying areas. Ventilation in dewatering systems ensures smooth operation by preventing airlocks, which can occur if water blocks the airflow in pipes.

Types of dewatering pumps include:

- Best submersible pump: These are often rated based on performance in dewatering tasks, handling water efficiently even in submerged conditions.

- Dewatering pump 1 hp: Suitable for smaller construction sites or household applications, where water needs to be removed from confined spaces.

- Submersible dewatering pump: Specifically designed to operate underwater, these pumps are ideal for areas where the pump may need to remain submerged for extended periods.

- Dewatering pumps for construction: These pumps are designed to handle larger volumes of water, often used in construction sites to remove accumulated groundwater.

- Dewatering pump manufacturers: Various manufacturers offer specialized dewatering solutions, ensuring pumps are designed to fit different construction and industrial needs.

Slurry and Sludge Pumps

In industrial settings, handling slurry or sludge requires pumps that can move solid-laden liquids efficiently. Slurry pumps are designed to handle thick liquids that contain abrasive particles, such as sand or gravel. Proper ventilation ensures these pumps can handle heavy loads without becoming airlocked.

- Slurry pump: These pumps are built to handle slurry, a mix of solid particles and liquids, common in mining, dredging, or wastewater treatment.

- Submersible slurry pump: This type of pump is designed to operate underwater while moving slurry, which can be abrasive and difficult to handle.

- Submersible agitator pump: These pumps come with built-in agitators to keep slurry moving and prevent it from settling, ensuring the pump can efficiently handle thicker materials.

- Slurry pump manufacturers: Leading manufacturers provide solutions for moving slurry in a variety of industries, ensuring pumps can withstand abrasive materials.

- Sludge pump: Sludge pumps handle thicker, more viscous materials like sewage sludge, which often includes semi-solid waste.

- Sewage sludge pump: This pump specifically handles the thick sludge generated by wastewater treatment processes.

Cutter Pumps

When sewage contains solid materials, such as rags or plastic, Cutter Pumps are invaluable. They shred large debris into smaller pieces to ensure the smooth operation of sewage systems. Cutter Pump Sewages require proper ventilation to maintain pressure balance and prevent system blockages.

- Cutter pump sewage: These pumps are commonly used in residential or commercial sewage systems where solid waste must be broken down before it can be pumped away.

The Importance of Ventilation in Sump Pumps

Sump pumps are primarily used in basements or low-lying areas to prevent flooding. These pumps move water from sump basins to outside drainage systems. Like other pump systems, sump pumps need ventilation to prevent airlocks and ensure continuous operation. Venting is particularly important for Submersible Sump Pumps, which are placed directly in water and could malfunction if air cannot circulate properly.

- Submersible sump pump: These are ideal for areas prone to flooding. They automatically activate when water levels rise, preventing basement flooding or water damage.

- Sump pump: The most common solution for managing water in basements or crawlspaces, sump pumps protect homes from water damage during heavy rainfall or snowmelt.

Single Phase and Three Phase Pumps

When it comes to powering pumps, different settings require different types of motors. For residential applications, single phase submersible pumps are common. These pumps operate efficiently on standard household electrical systems and are powerful enough to manage typical wastewater and sewage needs. On the other hand, commercial and industrial settings often use three-phase pumps for greater power and efficiency.

- Single phase submersible pump: These are ideal for residential or small-scale applications, providing sufficient power without requiring specialized electrical setups.

Ventilation in Drainage Pump Systems

Drainage pumps are essential for removing excess water from low-lying areas, particularly during or after heavy rains. Proper ventilation in these systems ensures that water can be efficiently moved out without creating pressure imbalances or airlocks.

- Submersible drainage pump: These pumps are designed to handle water that accumulates in basements, storm drains, or other low-lying areas. They work effectively in submerged conditions, making them suitable for flood-prone regions.

- Dewatering pump submersible: A specific type of drainage pump that operates while fully submerged, ensuring continuous operation in areas with standing water.

- Submersible drainage pump: Designed to remove large volumes of water, these pumps are used in both residential and commercial applications.

The Role of Manufacturers in Developing Efficient Pumps

Manufacturers play a crucial role in developing efficient and durable pumps for a variety of uses. From dewatering pump manufacturers to sludge pump manufacturers, companies are continually innovating to meet the growing needs of industries that depend on reliable wastewater management systems.

Conclusion

Proper ventilation is essential in all types of sewage and water management systems, whether you're dealing with a submersible pump, a dewatering pump, or a slurry pump. Ventilation helps prevent airlocks, pressure build-ups, and dangerous gas accumulations, ensuring that pumps operate efficiently and safely. From residential basements to large construction sites, maintaining proper ventilation in your pump system is critical to its success.

Whether you’re looking for the best submersible pump for your home or need a Cutter Pump Sewage system for industrial applications, understanding the role of ventilation will help ensure your system runs smoothly, protecting your property, environment, and health.