The Pros and Cons of Different Sewage Pump Materials

Sewage and wastewater management is a critical aspect of modern infrastructure, ensuring sanitation and public health. The choice of sewage pumps and their materials directly impacts the efficiency, durability, and cost-effectiveness of wastewater systems. In this blog, we will explore different pump materials, various submersible pump models, and the best options for specific applications like dewatering, slurry, and sewage sludge handling. We will also delve into the specific pros and cons of each, along with considerations for Cutter Pump Sewage, slurry pump, and Drainage pump needs. Let's begin by understanding the basic categories of pumps and their material construction.

Overview of Sewage Pumps and Their Materials

Sewage pumps are essential for transporting wastewater from lower levels (such as basements) to higher levels where the sewage can flow by gravity. These pumps come in different types, including submersible pumps, sludge pump, dewatering pumps, and cutter pumps.

1. Cast Iron Pumps

- Pros: Cast iron pumps are incredibly durable and can handle high pressure and heavy loads. This material is ideal for large sewage systems in industrial settings.

- Cons: Cast iron can rust over time, particularly in aggressive sewage environments that contain acidic or alkaline waste. Regular maintenance is required to prevent corrosion.

2. Stainless Steel Pumps

- Pros: Stainless steel is corrosion-resistant, making it suitable for handling sewage that may be chemically aggressive or acidic. These pumps are durable and long-lasting.

- Cons: Stainless steel pumps are typically more expensive than those made of other materials, making them a costlier option for smaller or residential systems.

3. Plastic (HDPE) Pumps

- Pros: Submersible pumps made from high-density polyethylene (HDPE) are lightweight and resistant to corrosion. These are ideal for residential and small commercial applications.

- Cons: Plastic is less durable than metal and can be prone to damage under heavy loads or impacts.

Submersible Pumps and Their Applications

Submersible pumps are designed to be fully submerged in the fluid they are pumping, which makes them highly efficient for sewage, wastewater, and slurry applications. Below, we explore different types of submersible pumps and their specific applications.

Submersible Pump

A submersible pump is an excellent option for sewage systems, particularly in areas where gravity cannot effectively move wastewater. These pumps are submerged directly into the sewage or wastewater, pushing the liquid upwards through the system.

Submersible Pump 1 HP

For residential and light commercial applications, a submersible pump 1 hp is typically powerful enough to handle moderate sewage loads. These pumps are ideal for small sewage pits or basements prone to flooding.

Submersible Pump 1.5 HP

A submersible pump 1.5 hp is a step up in power, offering more capacity for larger households or commercial buildings. These pumps are particularly suited for homes with multiple bathrooms or where sewage needs to be lifted a greater distance.

Submersible Water Pump

A submersible water pump is used primarily for removing clean or slightly dirty water from basements, swimming pools, or ponds. These pumps are not suitable for heavy sewage or slurry but are ideal for general drainage applications.

Dewatering Pump: Managing Excess Water

Dewatering pumps are designed specifically to handle large volumes of water, making them invaluable in construction, mining, and flood control scenarios. A dewatering pump can be either submersible or surface-mounted, depending on the application. These pumps are often used in emergency situations, such as after heavy rainfall or flooding.

Best Submersible Pump for Dewatering

When selecting the best submersible pump for dewatering, it's crucial to consider both the flow rate and the head (or lift) required. High-efficiency pumps are recommended for continuous operation in areas with frequent water buildup.

Dewatering Pump 1 HP

A dewatering pump 1 HP is perfect for small-scale operations or residential use, where large volumes of water must be removed from a flooded basement or similar area.

Submersible Dewatering Pump

A submersible dewatering pump is often used in areas where the pump needs to operate fully submerged. These pumps are highly efficient, as they push water out from the source directly rather than relying on suction.

Sewage Pump and Slurry Pump: Heavy-Duty Applications

Sewage pumps are designed to handle raw sewage, often containing solid waste. These pumps must be robust, typically made from cast iron or stainless steel, to ensure they can handle the challenging environment.

Slurry Pump

A slurry pump is similar to a sewage pump but designed to handle thick, viscous mixtures that contain a high percentage of solids. These are used in industries such as mining, where the materials being pumped can be abrasive.

Submersible Slurry Pump

The submersible slurry pump can handle highly abrasive slurries, making it perfect for applications where the fluid being pumped contains a high level of solids.

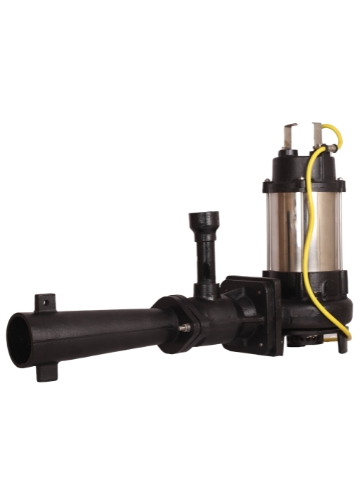

Cutter Pump and Sewage Sludge Pump

For sewage that contains solids that could clog standard pumps, a Cutter Pump is the ideal choice. A Cutter Pump Sewage system incorporates a cutting mechanism that breaks down solids before pumping them out. A sewage sludge pump is used to handle thick sludge, which can be difficult for standard sewage pumps to move efficiently.

Single Phase Submersible Pump: Residential Applications

A single phase submersible pump is commonly used in residential sewage systems where the electrical supply is limited to single-phase power. These pumps are efficient for smaller sewage systems but may not be powerful enough for larger commercial applications.

Drainage Pump and Submersible Drainage Pump

A drainage pump is specifically designed to move water from one location to another, typically in flood-prone areas or construction sites. A submersible drainage pump operates underwater and is highly effective at removing large amounts of water from flooded areas.

Submersible Sump Pump and Sump Pump

A submersible sump pump is used to remove water from a sump basin, often found in basements or crawl spaces. These pumps prevent flooding by activating automatically when the water level rises above a certain point. A sump pump can be either submersible or pedestal-mounted, depending on the application.

Sludge Pump and Submersible Agitator Pump

For handling thick waste materials, a sludge pump or submersible agitator pumpsubmersible agitator pump is ideal. These pumps are designed to move dense, heavy sludge through sewage systems without becoming clogged.

Dewatering Pumps for Construction

In construction, dewatering pumps for construction are crucial for keeping job sites dry. These pumps remove excess water that can accumulate due to rain, groundwater, or the construction process itself.

Slurry Pump Manufacturers, Sludge Pump Manufacturers, and Dewatering Pump Manufacturers

When selecting a slurry pump, sludge pump, or dewatering pump, it's essential to choose from reputable slurry pump manufacturers or dewatering pump manufacturers. These manufacturers provide pumps that meet the rigorous demands of industrial and construction environments.

Conclusion

Choosing the right pump for sewage, slurry, or dewatering applications requires a deep understanding of both the materials used in the pump and the specific requirements of the system. Whether you're in need of a submersible pump, sludge pump, Drainage pump, or cutter pump sewage system, selecting the appropriate model and material is essential for efficiency and longevity. With the right pump in place, you can ensure that your wastewater systems remain operational, efficient, and low-maintenance for years to come.