Submersible pumps are advanced fluid-handling solutions that have transformed water management across residential, agricultural, commercial, and industrial sectors. From draining flooded basements to handling sewage, slurry, and dewatering operations, these pumps are valued for their efficiency, durability, and ability to operate fully submerged. In this detailed guide, we explore the science behind submersible pumps, their working principle, components, applications, and future potential.

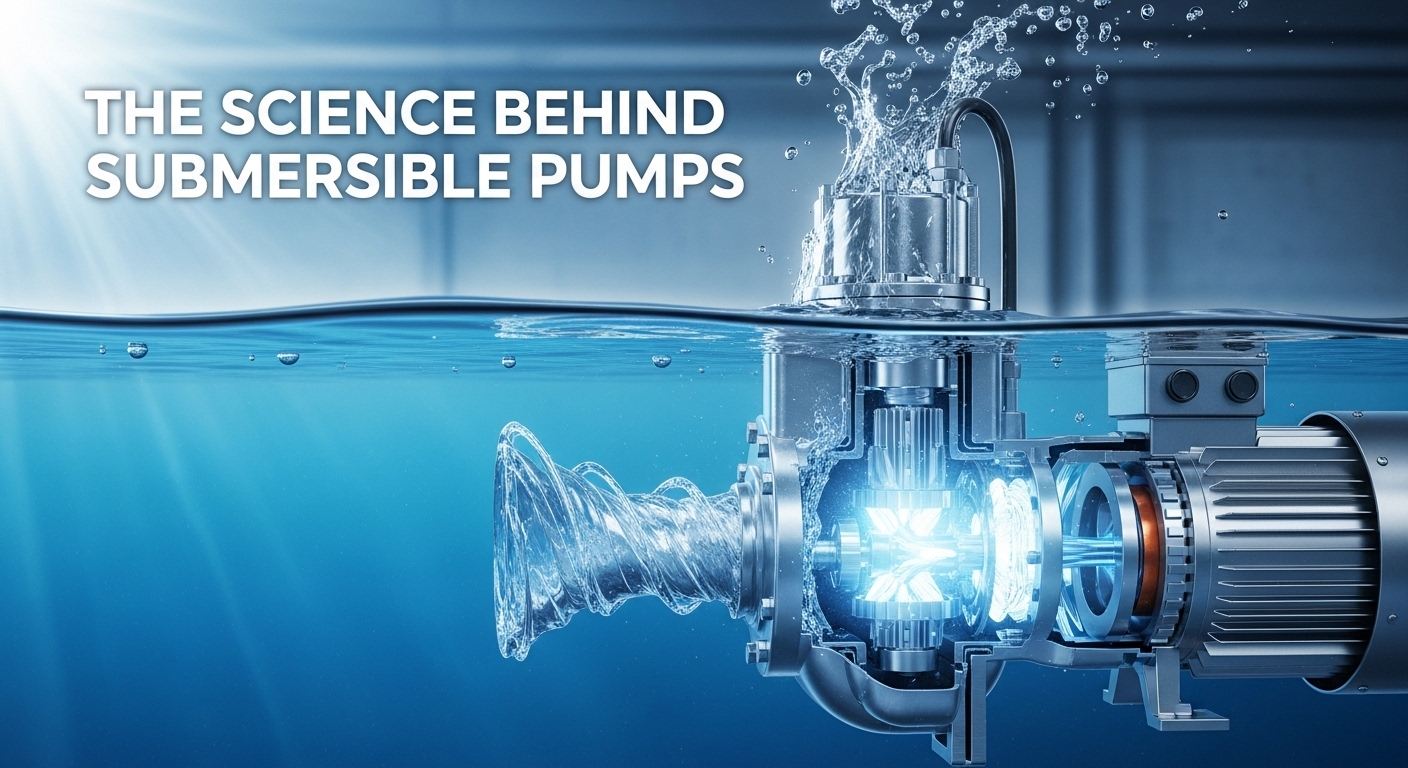

The Science Behind Submersible Pumps: How They Work and Where They Are Used

Key Takeaways

What Is a Submersible Pump?

A submersible pump is a centrifugal pump designed to function while completely submerged in liquid. Its hermetically sealed motor prevents water ingress, while the surrounding fluid helps dissipate heat, reducing the risk of overheating and improving operational efficiency.

Applications of Submersible Pumps

Working Principle of Submersible Pumps

The working principle of a submersible pump is based on centrifugal force. When the sealed motor rotates the impeller at high speed, liquid is drawn into the pump and pushed upward through the discharge pipe. Because the pump operates underwater, it avoids suction losses and cavitation commonly associated with surface-mounted pumps.

Advantages of the Submerged Design

Key Components of Submersible Pumps

Electric Motor

The electric motor is fully sealed and designed for continuous submerged operation, ensuring safe and reliable performance even in harsh environments.

Impeller

The impeller generates centrifugal force to move liquid efficiently. High-quality impellers significantly improve the performance of submersible water pumps used in clean and semi-clean water applications.

Seal System

The seal system prevents liquid from entering the motor housing, protecting internal components and extending the pump’s service life.

Pump Bowl Assembly

The pump bowl assembly houses the impellers and guides the liquid flow, helping maintain pressure and consistent discharge.

Functions of Submersible Pumps

Dewatering

Dewatering pumps are essential for construction sites, basements, tunnels, and flooded areas. A dewatering pump 1 hp is commonly used due to its compact design, portability, and energy efficiency.

Sewage Management

A submersible sewage pump is designed to handle wastewater containing solids and sludge. For more demanding conditions, cutter pump sewage systems grind solids before pumping, reducing the risk of clogging.

Slurry Handling

In mining and heavy industries, submersible slurry pumps are used to transport abrasive and solid-laden fluids efficiently.

Types of Submersible Pumps

| Submersible Water Pump | Domestic and agricultural water management | Corrosion-resistant and lightweight | Dewatering Pump | Construction sites and flood control | High flow efficiency and durability | Submersible Sewage Pump | Municipal wastewater systems | Efficient solid handling | Submersible Slurry Pump | Mining and industrial slurry | Abrasion-resistant components | Submersible Agitator Pump | Sludge and slurry suspension | Prevents sedimentation |

Advantages and Disadvantages of Submersible Pumps

| High efficiency and quiet operation | Maintenance can be complex | Versatile across multiple industries | Seal failure can affect performance | Reduced risk of overheating | Higher initial investment |

Innovations in Submersible Pump Technology

Recent innovations include abrasion-resistant materials, improved seal technology, energy-efficient motors, and smart monitoring systems that enable predictive maintenance and reduced downtime.

Maintenance Tips for Submersible Pumps

Future of Submersible Pumps

The future of submersible pumps is driven by sustainability and digital integration. Technologies such as IoT-based monitoring and solar-powered submersible pumps are shaping energy-efficient and environmentally friendly water management solutions.

Conclusion

Submersible pumps are essential across modern infrastructure, offering reliable performance for dewatering, sewage handling, slurry transfer, and water supply. Understanding their working principle, components, and applications helps users select the right pump, maximize efficiency, and ensure long-term operational success.