The Ultimate Guide to Submersible Pumps: Tips & Trends

Submersible pumps are an integral part of many industries, offering a versatile and efficient solution for a wide range of fluid-handling needs. These pumps are designed to operate underwater, making them highly effective for applications where other pump types might struggle. From residential water systems to large-scale industrial operations, submersible pumps provide reliable performance and are essential for various applications.

Definition of Submersible Pumps

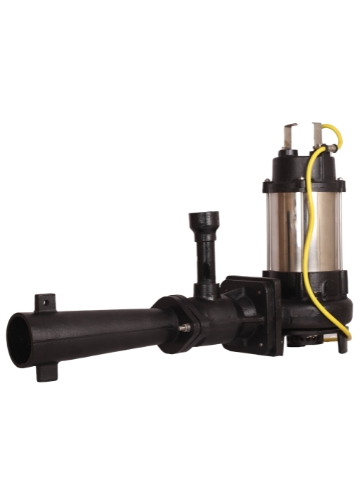

A submersible pump is a device that has a hermetically sealed motor close-coupled to the pump body. The entire assembly is submerged in the fluid to be pumped. The design ensures that the pump remains under the surface of the fluid, eliminating issues like cavitation that are often faced by other types of pumps.Overview of Submersible Pump Technology

Submersible pump technology has evolved significantly over the years. Modern designs focus on efficiency, durability, and adaptability to diverse conditions. The sealed nature of these pumps prevents the ingress of fluids, ensuring that the electrical components remain protected, even in harsh environments.Importance of Submersible Pumps in Various Industries

Submersible pumps are crucial in industries such as wastewater management, agriculture, oil and gas, and construction. Their ability to handle fluids with ease and efficiency makes them indispensable in operations that require reliable and continuous fluid movement.Types of Submersible Pumps

A. Wastewater Pumps

Wastewater submersible pumps are designed to handle sewage and other types of waste fluids. They are commonly used in municipal wastewater treatment plants and are built to manage solid-laden liquids.Applications in Sewage and Wastewater Management

These pumps are crucial in sewage systems, helping to transport wastewater from residential and commercial areas to treatment facilities. They can handle a variety of waste materials, including sludge and solids.Key Features and Specifications

- Robust Construction: Typically made from corrosion-resistant materials to withstand harsh wastewater environments.

- Impeller Design: Often features vortex or channel impellers to prevent clogging and ensure efficient solid handling.

B. Water Pumps

Submersible water pumps are used in both residential and commercial settings for various water management needs, such as providing water supply, drainage, and irrigation.Uses in Agriculture, Residential, and Commercial Settings

- Residential: Sump pumps in basements to prevent flooding, well pumps for water supply.

- Commercial: Used in large-scale water supply systems and for drainage in construction sites.

- Agricultural: Essential for irrigation systems and maintaining water levels in livestock facilities.

Differences Between Well and Sump Pumps

- Well Pumps: Designed to lift water from underground wells. They operate at significant depths and are vital for homes that rely on well water.

- Sump Pumps: Installed in basements or crawlspaces to pump out water and prevent flooding. These pumps typically activate automatically when water is detected.

C. Specialized Pumps

Specialized submersible pumps are designed for unique applications, such as dewatering and slurry handling.Dewatering Pumps

These pumps are used to remove water from construction sites, mining operations, or any area where water accumulation is a problem. They are lightweight, portable, and can handle various water types.Slurry Pumps

Designed to handle abrasive slurries commonly found in mining, dredging, and other industrial applications. These pumps are built to withstand heavy wear and tear.Industrial Applications

Submersible pumps are also used in industries such as oil and gas for extracting fluids from the ground and transferring them to processing facilities. They are crucial for maintaining efficient and safe operations.Applications of Submersible Pumps

A. Residential

Sump Pumps for Basement Flooding

Submersible sump pumps are a homeowner's first line of defense against basement flooding. These pumps detect water levels and automatically pump out excess water, preventing damage to property and ensuring a dry basement.Well Pumps for Water Supply

In areas without municipal water supply, submersible well pumps provide a reliable source of water for households. These pumps are installed deep within wells and can deliver consistent water pressure.B. Commercial and Industrial

Mining and Construction Dewatering

In mining and construction, controlling water levels is crucial for safe and efficient operations. Submersible dewatering pumps are employed to remove unwanted water, allowing work to proceed without disruption.Oil and Gas Extraction

Submersible pumps are used in the oil and gas industry to extract oil from wells and transfer it for processing. These pumps are designed to handle the specific challenges of pumping hydrocarbons, including high temperatures and pressures.Wastewater Treatment Facilities

In wastewater treatment, submersible pumps transport sewage and wastewater through various stages of treatment. They are built to handle large volumes and varying consistencies of waste material.C. Agricultural

Irrigation Systems

Submersible pumps are essential for irrigation, providing water to crops in an efficient and controlled manner. They can operate under various environmental conditions and deliver water to fields with minimal energy consumption.Livestock Watering

Ensuring a consistent water supply for livestock is critical in agriculture. Submersible pumps help maintain water levels in tanks and troughs, ensuring that animals have access to clean water.D. Environmental and Research

Groundwater Sampling

Submersible pumps are used in environmental research for groundwater sampling and monitoring. These pumps provide accurate data on water quality and help in assessing environmental impacts.Environmental Monitoring

In environmental monitoring, submersible pumps are used to maintain and monitor water levels in natural bodies of water, helping to preserve ecosystems and prevent flooding.Key Features and Specifications

A. Design and Materials

Corrosion Resistance

Submersible pumps are often constructed from stainless steel, cast iron, or thermoplastics to resist corrosion and extend their operational life, especially in harsh environments.Materials Used (Stainless Steel, Cast Iron)

- Stainless Steel: Offers excellent corrosion resistance and is suitable for a wide range of applications, including those involving aggressive fluids.

- Cast Iron: Provides strength and durability, making it ideal for heavy-duty applications.

B. Motor and Power Considerations

Types of Motors Used

- Electric Motors: Commonly used for their efficiency and ease of control.

- Hydraulic Motors: Utilized in specific industrial applications requiring high torque and pressure.

Efficiency and Power Consumption

Submersible pumps are designed to optimize energy use, with modern models offering high-efficiency motors that reduce power consumption and operational costs.C. Performance Metrics

Flow Rate

Flow rate is a critical parameter, indicating the volume of fluid the pump can move in a given time. It is essential to select a pump with the appropriate flow rate for the intended application.Head Pressure

Head pressure refers to the height the pump can lift fluid. It is crucial for applications involving significant elevation changes or deep well installations.Efficiency Curves

Efficiency curves provide insights into a pump’s performance at various operating conditions. Understanding these curves helps in selecting a pump that matches the system's specific requirements.Installation and Maintenance Tips

A. Installation Guidelines

Proper Sizing and Selection

Choosing the right pump involves evaluating factors such as fluid type, flow rate, and head pressure requirements. Proper sizing ensures efficient operation and prevents issues like overloading or insufficient flow.Installation Procedures and Best Practices

- Ensure the pump is correctly aligned and secured.

- Follow manufacturer guidelines for electrical connections and safety precautions.

- Use appropriate seals and fittings to prevent leaks.

B. Maintenance Practices

Routine Inspections and Servicing

Regular inspections and maintenance are vital to ensure the longevity and reliability of submersible pumps. This includes checking for wear and tear, cleaning components, and replacing damaged parts.Troubleshooting Common Issues

- Clogging: Clear any obstructions from the impeller or intake screen.

- Leaks: Inspect seals and gaskets for damage and replace them if necessary.

- Motor Issues: Check electrical connections and ensure the motor is operating within its specified range.

C. Safety Considerations

Electrical Safety Measures

- Ensure all electrical connections are watertight and properly insulated.

- Install ground fault circuit interrupters (GFCIs) to prevent electrical shocks.

Handling and Storage Precautions

- Store pumps in a dry, clean environment when not in use.

- Handle with care to avoid damage to components.