Winterizing Your Sewage Pump: Essential Tips for Cold Weather

As winter approaches and temperatures drop, the importance of preparing your sewage and submersible pumps for the cold season cannot be overstated. Cold weather can wreak havoc on these critical systems if not properly winterized, leading to frozen pipes, pump malfunctions, or complete breakdowns. These issues can lead to costly repairs and potential water damage. This comprehensive guide will walk you through the essential steps needed to winterize your sewage pump, ensuring that it operates smoothly throughout the colder months.

Understanding the Importance of Winterization

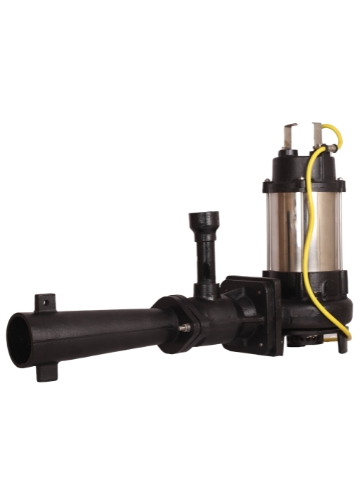

Before delving into the steps of winterization, it’s essential to understand why it's necessary. submersible water pump, sewage pump, and sludge pumps operate in cold and often wet conditions, which can become problematic when temperatures drop below freezing. If water freezes in the pump or discharge lines, it can cause cracks or bursts in the pipes, leading to leaks and system failure. Taking the necessary precautions to winterize your pump, whether it's a submersible sewage pump or a drainage pump, will save you from unexpected breakdowns and costly repairs.

1. Inspect the Pump and Pit

The first step in preparing your sewage pump for winter is a thorough inspection of both the pump and the sump pit. Clear away any debris, dirt, or sludge from the pit that may have accumulated over time. Clogged or dirty systems are prone to malfunctioning, and debris can cause backups or freezing issues during winter.

If you are using a submersible pump or a submersible sump pump, check for any signs of wear and tear, such as cracks or rust. A well-maintained pump is less likely to freeze or malfunction when exposed to freezing temperatures. For those utilizing high-powered options like the submersible pump 1 hp or submersible pump 1.5 hp, it's especially important to check the motor and ensure it’s running smoothly.

2. Clear and Insulate the Discharge Line

One of the biggest threats to a sewage sludge pump during winter is the potential for the discharge line to freeze. To avoid this, ensure that the discharge line is free from any blockages. You should also add insulation around the line to help protect it from freezing temperatures. Insulation will help keep the water moving even during sub-zero temperatures, preventing ice from forming and causing the system to back up.

3. Test the Backup Power System

Winter storms often bring power outages, which can affect the operation of your submersible dewatering pump or submersible drainage pump. To ensure continuous operation during a blackout, test your backup power system. Many sump pumps rely on battery backups or generators to function during a power outage. Make sure the batteries are fully charged, and the backup system is in good working order before the cold weather hits.

For homeowners with heavy-duty systems like the dewatering pump 1 hp or those dealing with construction-related projects and using dewatering pumps for construction, ensuring that your backup system can handle the load is critical.

4. Check the Float Switch and Alarms

Another critical component to check is the float switch on your submersible pump or Cutter Pump Sewage system. A frozen or malfunctioning float switch can prevent the pump from activating when needed, leading to flooding or backup issues. Ensure the switch is free from ice buildup and operates smoothly.

Installing alarms that notify you of system malfunctions or failures is another useful step. If your sludge pump or submersible slurry pump fails due to freezing or other issues, alarms can alert you to potential problems before they escalate.

5. Install a Sump Pump Cover

Installing a cover over your sump pump can offer additional protection against freezing. Sump pump covers help to maintain a stable temperature around the pump, reducing the risk of it freezing in extreme cold. Covers also prevent debris from entering the sump pit, which can be particularly helpful for submersible sewage pumps or slurry pumps that are at risk of clogs.

For those who utilize cutter pumps or submersible agitator pumps that handle tough materials like waste or slurry, a sump pump cover helps ensure smoother operation during winter months.

6. Schedule Professional Maintenance

While DIY maintenance can go a long way, there’s no substitute for professional care. A licensed plumber or pump specialist can provide thorough inspections and winterization services for your sewage pump, submersible slurry pump, or drainage pump. Professionals have the expertise to detect early signs of wear and tear that might be missed during a self-inspection. They can also ensure that your system is fully prepared for freezing temperatures, reducing the risk of failure.

For industrial applications, it may also be helpful to consult with slurry pump manufacturers or sludge pump manufacturers to get specialized winterization tips for your specific equipment.

7. Monitor Your System During Winter

Once your submersible dewatering pump or sewage sludge pump is winterized, it's important to continue monitoring the system throughout the cold months. Regularly check for ice buildup, and ensure that water is still flowing freely through the discharge line. If you’re using a submersible sewage pump or a single phase submersible pump, monitor its performance, and listen for any unusual noises, which may indicate freezing or blockages.

For those who are using dewatering pumps for construction or dewatering pump manufacturers products on job sites, additional monitoring is essential to prevent delays caused by freezing pumps.

8. Consider Upgrading to a More Efficient Pump

Winter is also a good time to consider upgrading your system if your current pump isn’t performing as well as it should. If your submersible water pump or slurry pump struggles to handle the demands of your home or construction site, upgrading to the best submersible pump available can make a significant difference in both efficiency and reliability.

Options like a submersible pump 1.5 hp or submersible agitator pump provide increased power and efficiency, ensuring better performance in colder conditions. Additionally, many dewatering pump manufacturers offer models designed specifically for cold weather performance, making them ideal for winter projects or areas that experience extreme weather.

Conclusion

Winterizing your sewage pump, submersible sump pump, or dewatering pump is essential to ensure it functions reliably during cold weather. By inspecting your system, insulating discharge lines, testing backup power, and taking other preventive steps, you can avoid the headaches and costs associated with pump malfunctions in winter.

Regular maintenance and professional inspections will keep your system running smoothly, whether you're using a submersible slurry pump, cutter pump sewage, or a submersible dewatering pump. With the right precautions in place, you can rest easy knowing your pump is ready to handle the harshest winter conditions.

For those in industrial or construction settings, consulting with slurry pump manufacturers, sludge pump manufacturers, or dewatering pump manufacturers ensures that your systems are optimized for winter use. Investing in a high-quality submersible pump or dewatering pump now will pay off in the long run, helping you avoid costly repairs and downtime during the cold season.